Screw rod induction hardening and tempering furnace

Features:

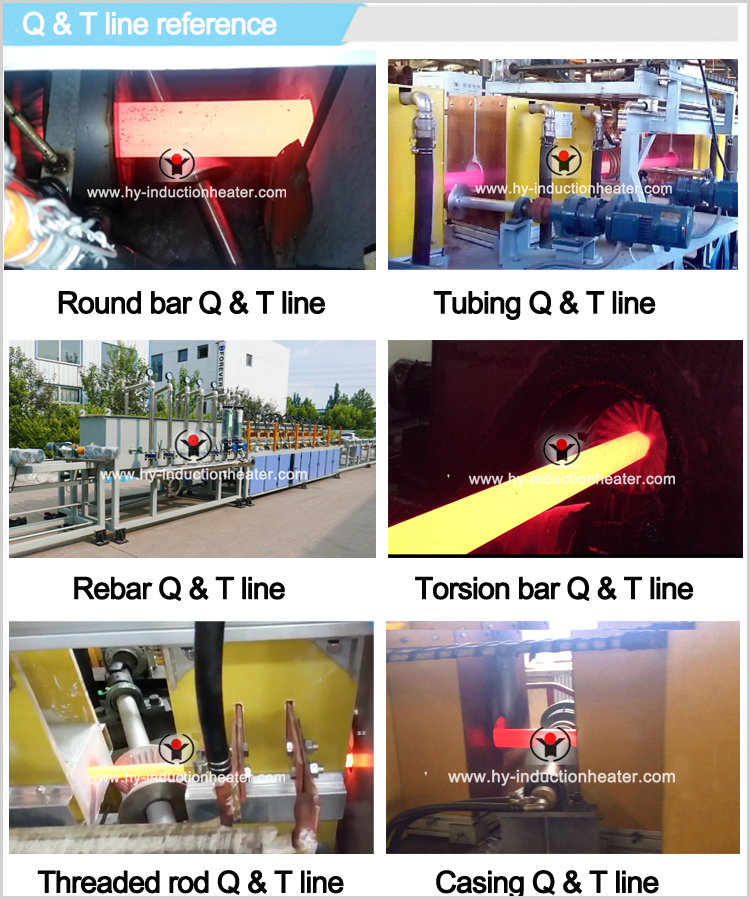

Application: Hardening & Tempering

Material Heated:Screw rod

Rod Diameter reference: Ø10~Ø110mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

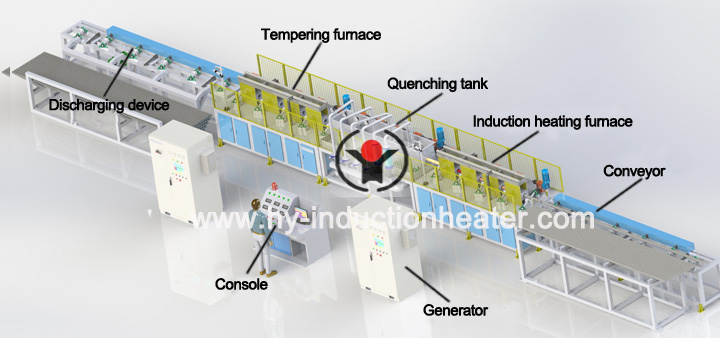

Compared with coal furnace and gas furnace, induction heating furnace can meet the requirements of environmental protection. It can be applied to online continuous heating, quenching and tempering. The degree of automation is high and only two people can operate complete sets of equipment.

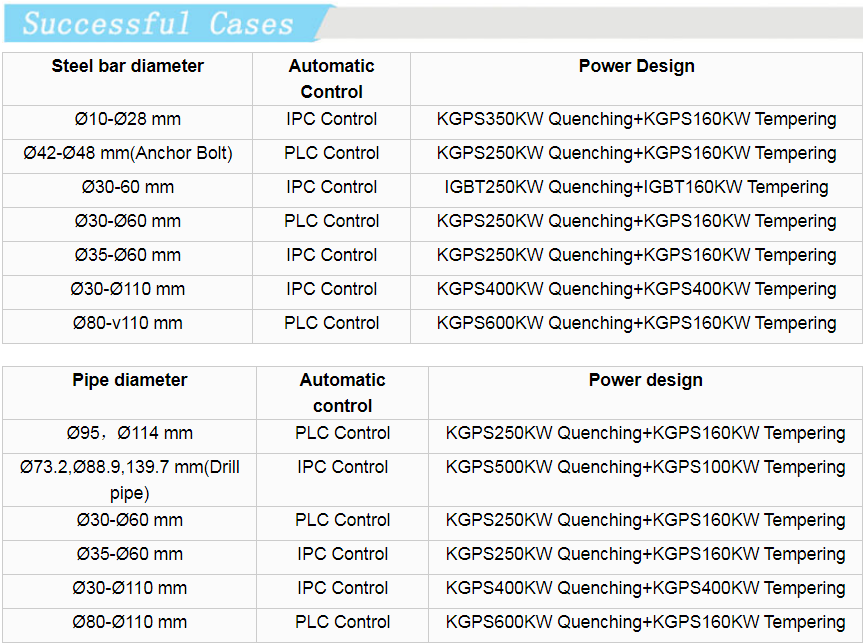

Our company designed and manufactured two sets of screw rod hardening and tempering line for our China customer, and their screw rod size is ø10-28mm and ø30-110mm. Due to the screw rod has thread on the rod surface, we adopt special technology to achieve the hardening and tempering.

The configuration and characteristics of screw rod hardening and tempering furnace :

1. The screw rod hardening and tempering line body is made of special materials which is welded after heat treatment.

2.Feeding motor: frequency conversion speed regulation;

3. Temperature measurement: We set four pyrometers for the whole line, the temperature for quenching and tempering can be measured online, achieving temperature closed loop control.

4.Inductor replacement: manual;

5.The generator can adjust the power and frequency as per the different load;

6.Water pressure protection, flow protection, air pressure protection;

7.Alarm: Screw rod hardening and tempering line sound / light failure alarm, control interface display alarm and record;

8. Inductor and sprinkler cooling interface: stainless steel / Brass quick change connector for Screw rod hardening and tempering line

9. The screw rod hardening and tempering linecontrol system can carry out monitoring and recording of various processing parameters, and has the functions of historical inquiry, on-line monitoring, output printing, etc.

10. Loading and unloading: the automatic loading and unloading mechanism can be configured to realize automatic feeding and unloading. It can be processed automatically with the last step.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet induction heater in China; Glad to be your business partner in induction heating field.