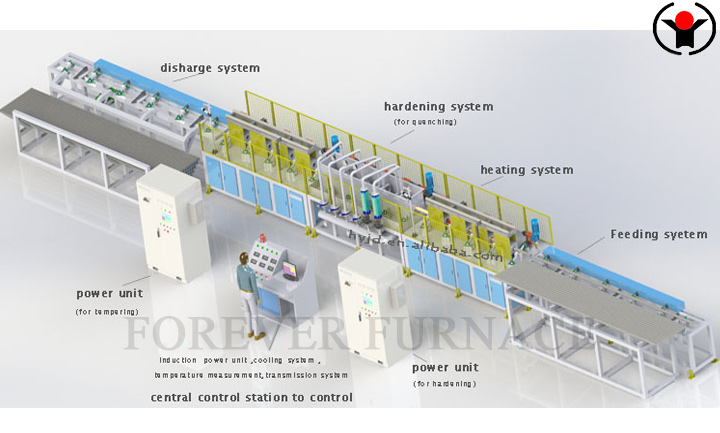

Forever Electromechanical specializes in producing plate quenching furnaces. As long as you tell us your workpiece size, product specifications, heating temperature, process requirements, and the heating method you are currently using, Forever Electromechanical will provide reasonable suggestions for your process improvement and choose the appropriate plate induction hardening furnace for your workpiece requirements. This will reduce production costs, improve quality, and efficiency, making your products more competitive in the same industry.

Induction heating equipment sprayer: Forever Electromechanical uses a circular spray device made of stainless steel material, which is installed at the discharge end of the plate quenching furnace sensor. The workpiece passes through the sprayer, and high-pressure cooling water is sprayed from the spray holes on the inner wall of the sprayer to quench the workpiece. There is a water collection tank below the sprinkler, and the cooling water flows into the quenching circulating water tank through the water collection tank.

plate induction hardening machine inductor: The inductor copper tube is wrapped with T2 oxygen free copper, with a wall thickness of 3.0mm or more. The inductor insulation material has high strength, high temperature resistance, and longer service life; The input and output ends of the sensor are encapsulated with 5mm purple copper plate, which greatly reduces magnetic leakage and extends its service life. The sensor chassis is made of high-strength aluminum alloy to reduce the impact of magnetic leakage and heat generation on other components. A water-cooled roller is installed between every two sensors, and each roller is equipped with a variable frequency speed motor.

Dual color infrared thermometer and display: The temperature measurement device for the board quenching furnace adopts a non-contact dual color infrared thermometer, which can be used for temperature measurement in harsh environments with dust and smoke. Equipped with temperature display and multiple output interfaces for use with printers or recorders. There is a temperature display on the external control panel, which has the characteristics of high accuracy, good reliability, and strong resistance to environmental influences. When the measured temperature exceeds the set value, there are sound and light alarm functions.

Characteristics of steel plate heat treatment machine:

1. High reliability

Adopting reliable intermediate frequency induction design circuit principles ensures high reliability and a success rate of over 99% for startup programs.

2. The entire steel plate heat treatment furnace adopts PLC fully automatic control program

Automatic and continuous system monitoring equipment ensures safe and reliable quenching process

3. Low noise

The design and installation of steel structures fully consider reducing vibration, thereby greatly reducing noise levels; The front baffle and dust hood of the furnace also fully consider the noise reduction effect.

4. Easy installation, operation, and maintenance

The advanced module design concept greatly simplifies and accelerates the installation speed of board induction quenching furnaces. The system operation and monitoring are simple, and the user interface is user-friendly.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-25-2025