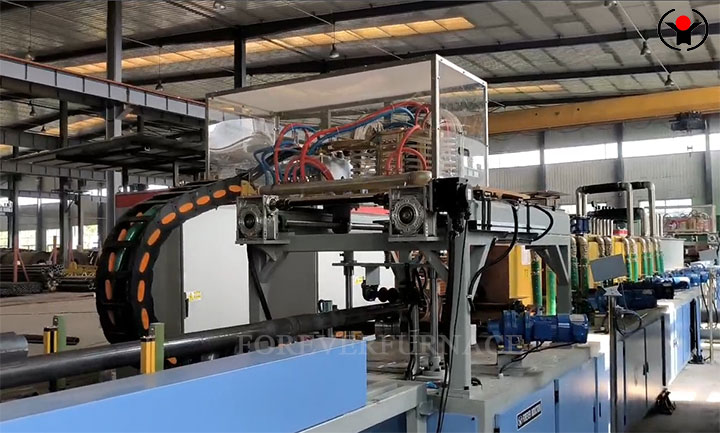

The Forever Oil pipeline induction heat treatment line is an efficient heat treatment system designed specifically for oil casing. Its core is to achieve rapid quenching and tempering through induction heating, ensuring that the casing has high strength, wear resistance, and fatigue resistance.

Core components and functions of the Drilling pipe hardening and tempering furnace

(1) Induction heating system

Power module

Intermediate frequency/ultrasonic frequency power supply (1-50kHz): Select the frequency according to the thickness of the casing wall. Intermediate frequency (1-10kHz) is suitable for thick walled pipes (such as Φ 244.5mm × 11.99mm), and ultrasonic frequency (10-50kHz) is used for rapid heating of thin-walled pipe surfaces.

Power regulation: dynamically match heating power (usually 200-2000kW) to ensure austenitization temperature (such as N80 steel needs to reach 880-920 ℃).

Inductor coil

Segmented design: Multiple sets of coils are independently controlled to achieve axial uniform heating (temperature difference ≤± 10 ℃).

Quick change structure: Suitable for different sleeve diameters (such as 4 ݪ “to 9 ⅝”), with high-temperature resistant ceramic lining inside the coil to prevent arcing.

(2) Quenching system

Spray cooling device

Multi nozzle array: high-pressure water/polymer quenching solution (such as PAG) is uniformly sprayed, with controllable cooling rate (>50 ℃/s) to avoid incomplete martensitic transformation.

Closed loop temperature control: flow sensor+temperature feedback, adjust quenching liquid pressure (0.2-0.8MPa) and temperature (20-40 ℃).

Quenching medium circulation

Filtration and cooling: remove impurities from the oxide skin and maintain the purity of the medium; The heat exchanger maintains a constant temperature of the quenching liquid.

(3) Tempering system of the Oil casing pipe hardening and tempering furnace

Induction tempering unit

Low temperature induction heating (400-650 ℃): eliminates quenching stress and adjusts hardness (such as the hardness of P110 steel after tempering HRC25-32).

Insulation control: PID adjusts power to ensure that the tempering temperature fluctuation is ≤ ± 5 ℃.

Hot air circulation assistance (optional): used for compensating the uniformity of tempering in ultra thick walled casing.

(4) Conveyor and positioning system

roller conveyor

Variable frequency speed regulation: matching heating/cooling time, adjustable conveying speed of 0.5-3m/min.

Alignment device: Laser positioning ensures that the axis of the casing is concentric with the sensor (deviation ≤ 1mm).

Rotation mechanism

Servo driven rotation (10-30rpm): evenly heats the steel pipe in the circumferential direction, avoiding “spiral soft bands”.

(5) Automated control system

PLC/HMI control

Process curve programming: Store parameters for different steel grades (such as J55 quenching temperature of 850 ℃, tempering temperature of 600 ℃).

Fault self diagnosis: monitoring water pressure, power overload, temperature deviation, etc., automatic shutdown protection.

Data traceability: SCADA system records key parameters such as heating temperature and cooling rate, and generates heat treatment reports (compliant with API 5CT certification requirements).

(6) Auxiliary system

Closed loop cooling tower: provides pure water cooling for power supply and sensors (flow rate ≥ 50m ³/h, inlet water temperature ≤ 30 ℃).

Dust removal and exhaust gas treatment: Exhaust device collects quenching oil fumes, which are discharged after electrostatic dust removal.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-27-2025