Intelligent Control System for Induction Heating Process

● Provide remote console with touch screen or IPC system on user demand.

● Customized human-machine interface,high user-friendly operation instruction.

● All-digital, high depth adjustable parameters that make you easy to control the equipment with great efficiency.

● Strict purview management system and perfect one key to restore system.

● Provide corresponding language switching according to different countries and regions.

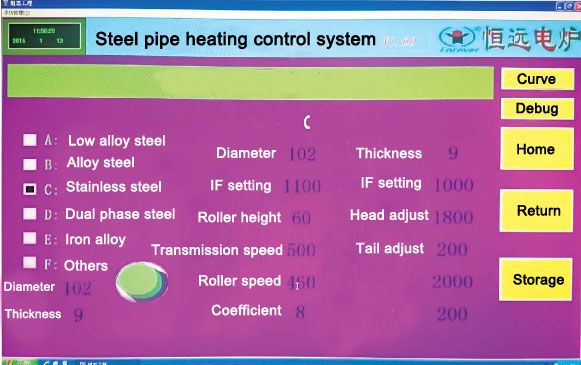

Recipe management function: Powerful recipe management system–after inputting parameters of steel grade, outer diameter and wall thickness, this system can automatically call relevant parameters, no need to manually record, check, input required parameters for various work piece.

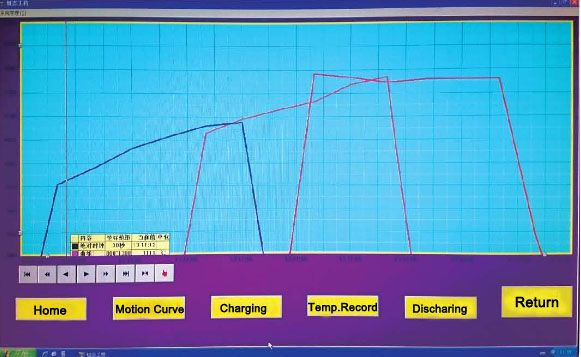

Historical curve function: The traceable process historical curve(IPC system standard) and registration accuracy accurate to 0.1 seconds reappear the treatment temperature trend for individual product vividly and accurately. Capacity storage space up to 1T can store product process records in decades years permanently.

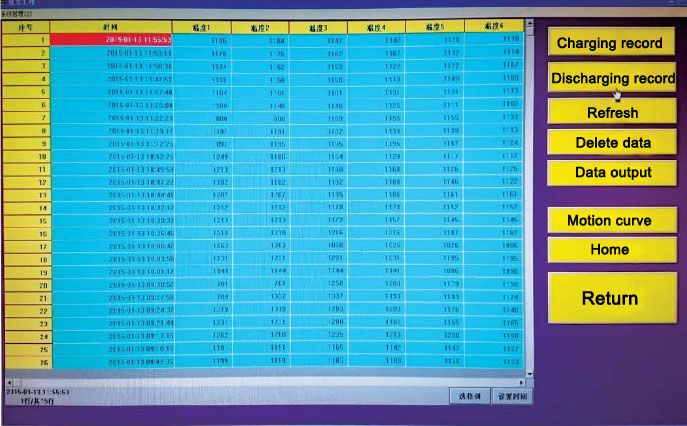

Historical record: The traceable process data form can take out multiple sets of sample points from each product and reappear treatment temperature values for individual product in every stages. The touch screen can store about 30,000 process records which can be copied in U disk or network backup; The IPC system can store product process records in decades years permanently without restriction of storage space.