Tubing quenching tempering machine

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Diameter range: not limited

Heating way: Induction heating

Product Detail

Application Video

Product Tags

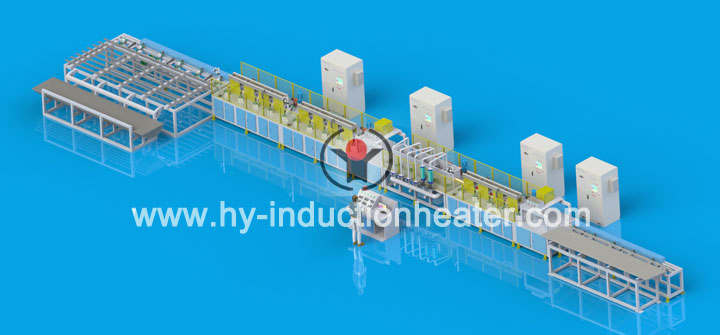

Tubing quenching tempering line

● Product name:Tubing quenching tempering line, Tubing induction heat treating line

● Diameter range: Not limited

● Length range: Not limited

● Product strength: Uniform heating, uniform quenching, good heat treatment effect

● Industry: Oil industry

Over two years development together with oil casing & tubing plant, Forever casing quenching tempering process has been mature. The practice proves that this process can make the casing quenching tempering line run in stable condition.

Successful case: Φ73.02-139.70 Philippines oil casing & tubing plant

● Power supply composition : The complete set of system consists of four sets of power supplies.

Quenching 500KW / 1000HZ

Quenching pier special temperature compensation: 120KW / 1000HZ

Tempering 200KW / 500HZ

Tempering pier special temperature compensation: 80KW / 500HZ

● Transmission roller table: The angle between roller axis and work piece axis is 18 ~ 21 °. The work piece is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● Feeding system: Independent motor reducer drive for each axis , independent inverter control; flexible design speed differential output, section speed control.

● Piers temperature compensation system: As the pier diameter is different from the middle part of the sleeve, we design special temperature compensation system. Induction furnace for temperature compensation can be online tracking and compensate temperature precisely ensuring that the temperature difference between the pier and middle part can be controlled within 20℃.

● Recipe management function: Powerful recipe management system–after inputting parameters of steel grade, outer diameter and wall thickness, this system can automatically call the relevant parameters, no need to manually record, check, input required parameters for various work piece.

● Multiple closed-loop function: For power supply system unstable of underdeveloped areas and countries, we have designed high-grade temperature, voltage and other multi-channel closed-loop system.Under the conditions that the supply voltage fluctuation is up to 20% and intermittent working with generator set, our equipment can still guarantee high consistency of product process.

If you are interested in our induction heating equipment, please send us inquiry

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of heat treatment furnace in China; Glad to be your business partner in induction heating field.