Induction hardening and tempering

Features:

Application: Quenching & Tempering

Material Heated:S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Diameter range: ø10-120mm

Heating way: Induction heating

Product Detail

Application Video

Product Tags

Induction hardening and tempering

● Product name: Induction hardening and tempering furnace, induction heat treating furnace

● Steel grade:S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

● Bar size :Ø20~Ø60mm

● Bar length : 3-7m

● Power consumption:480~500kw/h per ton

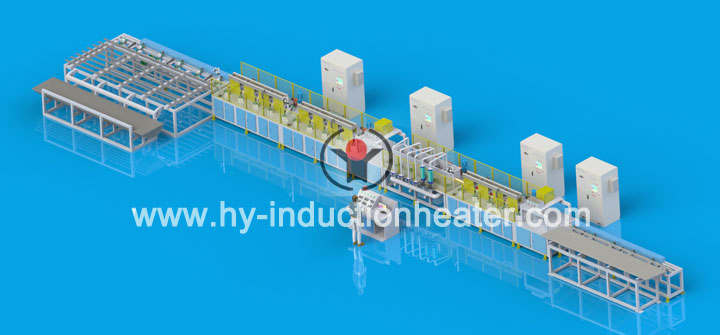

The Induction hardening and tempering line is provided with Forever unique intelligent MF quenching system, tempering system, closed cooling system, storage platform, quenching machine feeding device, infrared temperature measurement, spray cooling system, tempering mechanical feeding machine and receiving platform & remote console.

The Induction hardening and tempering line is used for quenching and high temperature tempering of 25-60 steel bars.The heating way is continuous induction heating.The complete induction hardening and tempering line only need workers to put steel bars on the storage platform, other actions are done automatically by the system under the control of PLC. The complete production line is controlled by computer automatically and all the running parameters, quenching tempering parameters, temperature will be saved,display and record automatically. The system will run as per perset technical parameters.

| Item | Name(Specification) | Quantity | |

| 1 | MF power supply for quenching KGPS350KW/2000~3000Hz | 1 set | |

| 2 | MF power supply for tempering KGPS200KW/1000~1500Hz | 1 set | |

| 3 | Inductor for quenching | GTR(Ø25~Ø30)×360 | 1 set(Six segments in all) |

| GTR(Ø32~Ø39)×360 | 1 set(Six segments in all) | ||

| GTR(Ø40~Ø50)×360 | 1 set(Six segments in all) | ||

| 4 | Inductor for tempering | GTR(Ø25~Ø30)×390 | 1 set(Eight segments in all) |

| GTR(Ø32~Ø39)×390 | 1 set(Eight segments in all) | ||

| GTR(Ø40~Ø50)×390 | 1 set(Eight segments in all) | ||

| 5 | Tempering holding box(Ø25~Ø50)×390 | Three segments | |

| 6 | 350KW Resonant capacitor and furnace frame(including stainless pipe) | 1 set | |

| 7 | Quenching box(including stainless steel water spray ring, flow meter and conveyor roller) | 1 set | |

| 8 | 200KWResonant capacitor and furnace frame(including stainless pipe) | 1 set | |

| 9 | Equipment connection line (MF power supply to capacitor cabinet) | Two pairs | |

| 10 | Storage platform 6.0 meters | 1 set | |

| 11 | Roller table for feeding 6.0 meters | 1 set | |

| 12 | Roller table for discharging 6.0 meters | 1 set | |

| 13 | Receiving paltform 6.0 meters | 1 set | |

| 14 | Infrared thermometer & displaty(Quenching temp.measurement+temepring temp.measurement) | 2 sets | |

| 15 | Remote console(Frequency control and temperature control, IPC, start etc.) | 1 set | |

| 16 | Independent gear reducer drive roller (including water-cooled roller) | 23 sets | |

| 17 | Feeding roller power system (motor speed reducer) | 1 set | |

| 18 | Discharging roller power system (motor speed reducer) | 1 set | |

| 19 | Enclosed cooling machine | 1 set | |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.