Flat bar hardening and tempering line

Features:

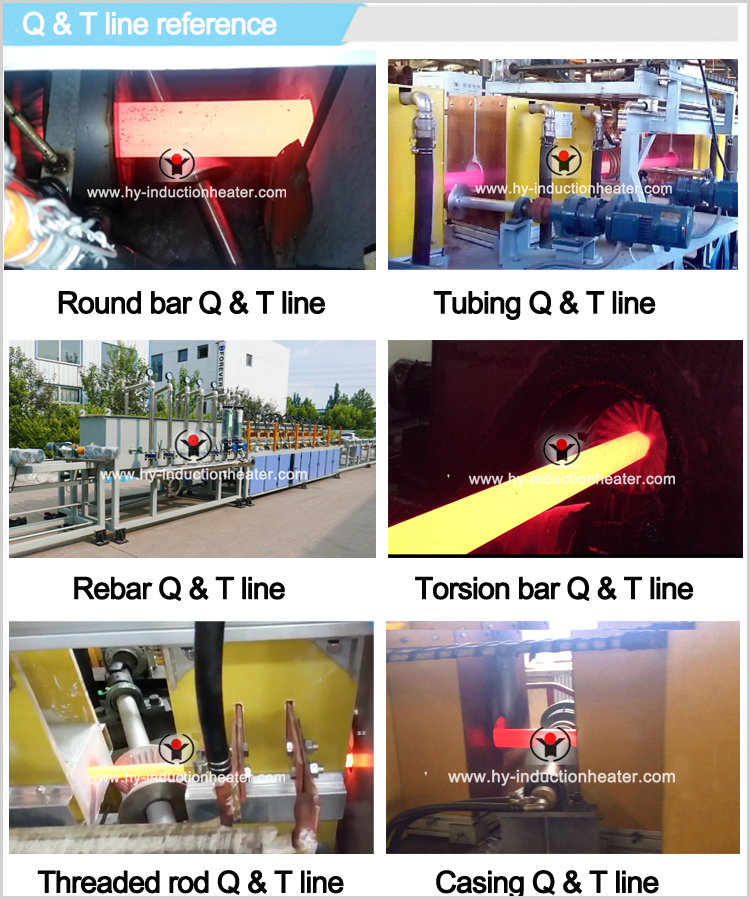

Application: Hardening & Tempering

Material Heated:Flat bar(Machine tools)

Length Allow:Not limited

Product Detail

Application Video

Product Tags

With the development of Forever hardening and tempering furnace, the workpiece that can use this process is more and more. This year Forever receive one order for flat bar hardening and tempering line: 40*10/60*30 Flat bar hardening and tempering line.

● Material: Carbon steel, alloy steel

● Process:Hardening and tempering

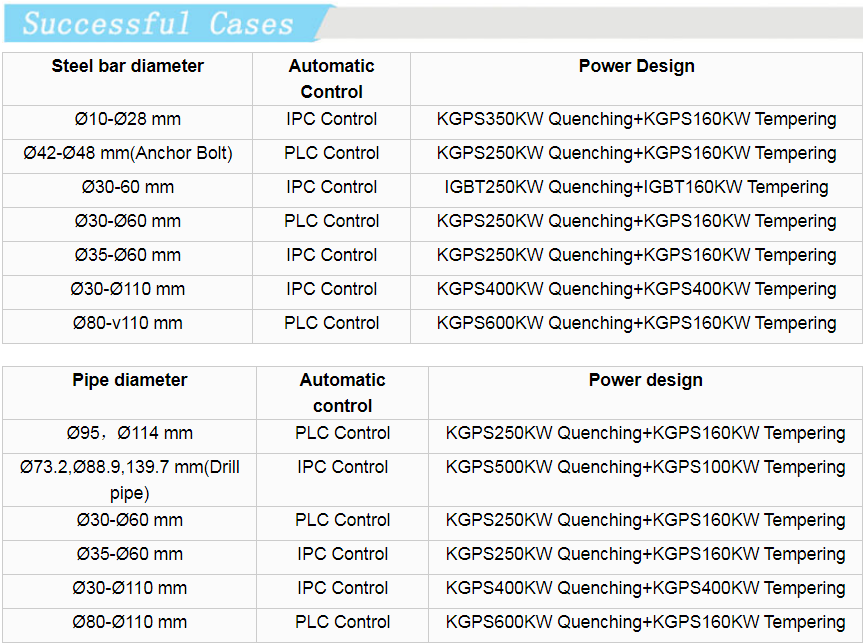

● Power designed:As per user’s hourly capacity requirement.

● Heating way:Electrical induction heating

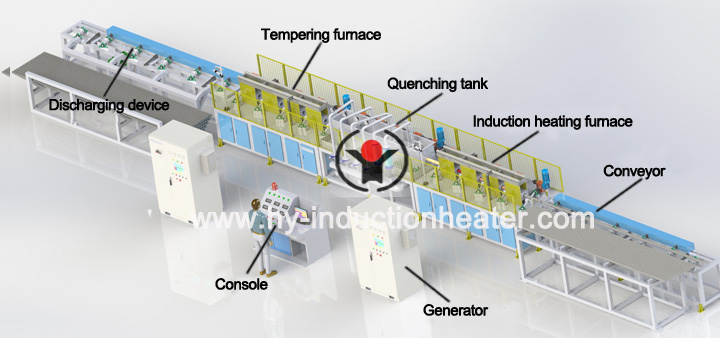

● Conveying mode:Roller table

● Control mode:Automatic controlled by SIEMENS PLC

Advantages of hardening and tempering furnace(Compared with fuel furnace and resistance furnace)

●Because the heat is generated inside the heated workpiece, the heating speed is high, and the efficiency is high, the surface of the workpiece is less oxidized and decarbonized, and raw materials are saved.

●Good working environment, no pollution, high degree of automation.

Compared with coal furnace and gas furnace, induction furnaces can meet the requirements of environmental protection. It can be applied to online continuous heating, quenching and tempering. The degree of automation is high and only two people can operate complete sets of equipment.

The characteristics of the intelligent Flat bar hardening and tempering line:

● Conveying roller: As the flat bar is special shape and can not rotate by itself, the uniform heating and cooling during hardening and tempering process is a difficulty. Forever engineer adopts special mechanical device to solve it and the feedback from the users has proved that this design is workable and get good effect.

● Roller table grouping: the feed group, the inductor group and the discharging section are independently controlled, which is beneficial to continuous heating without causing gaps between the parts.

● Temperature closed loop system: Both hardening and tempering adopt the American Raytek infrared thermometer and closed loop control system with SIEMENS S7 to precisely control temperature.

● IPC system: real-time display of the state of the working parameters, memory, storage, printing, fault display, alarm and other functions.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet induction heater in China; Glad to be your business partner in induction heating field.