Induction furnace forging machine

Features:

Application: Forging & Forging

Material Heated:Carbon Steel & Alloy Steel

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name:

Typical Application:

Bar & Billet induction forging heating machine is used for forging rod,billet of copper and steel.

Forever company has a long history of supplying induction forging furnace for forging for a variety of applications throughout the foundry industry. We pride ourselves on supplying the most reliable, durable and efficient induction induction forging furnace for forging available to the industry today. Our line of induction forging furnace range in capacity from 100KW to 8000KW.

Induction forging process refers to using the induction heater to heat metal bar, rod, billet or bloom before prior to forging. After heating up the material, the forging process will be done on different types of machines: Forging hammer, mechanical press, hydraulic machine, screw press etc.

Brief introduction to the induction forging furnace:

It is used for continuous through heating of regular round bar of stainless steel, copper, aluminum and other square workpiece. It can be used as whole heating material, and can also be used for local heating of end material, such as end heating, middle part heating, etc.

The basic components of the induction forging furnace are as follows:

It includes medium frequency converter, compensation capacitor box and worktable, induction coil, feeding mechanism, etc. According to different application requirements, it may include infrared thermometer, temperature controller, feeding and winding device.

Material heating temperature for hot forging:

• Steel 1200º C

• Brass 750º C

• Aluminum 500º C

Features of Induction Heating forging furnace:

● Efficient !

Our machine that adopts German Siemens IGBT model can reach a set temperature within two seconds.

● Speed controllable !

You can adjust the machine to acquire the speed you need.

● Safe and reliable !

It is equipped with many safety system. Any mistake can be alerted by the self-protection buttons, over-current, over-voltage, over-hot, water shortage etc.

● Easy to install and operate !

Any unprofessional worker can learn how to use it well within 3 minutes.

● Environmental !

No pollution. It conforms to the requirement of the national environmental protection.

● Economical !

This induction way saves 20%-30% electricity than other ways.

● Longlasting work !

A unique cooling circulation system equipped in the machine ensures long-lasting work.

● Step-less !

Machine power can be adjusted step-less.

● Customized !

Our machine can be changed partially according to your needs.

● Temperature controllable !

Not only the temperature of heating but also the time of heat and heat preservation can be set.Thus operator needn’t set the technical numbers again and again.

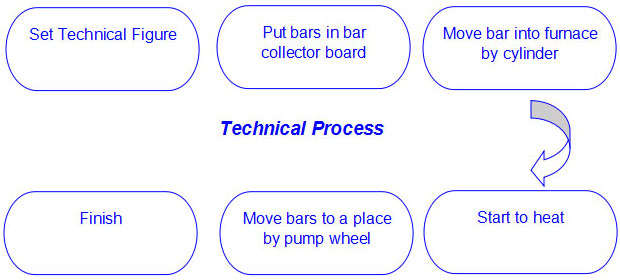

Technical process of Induction Heating forging furnace:

As our billet induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for Customized price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.