Thick wall steel tube induction annealing machine

Features:

Product name:Induction Annealing equipment for thick walled steel pipes

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304316, 20Cr, 40cr, 20CrIo, 35CrIo, 42CrHo, 40CrNIMIO, GCr15, 651m, 501m, 50Cr, 3Cr2w8v, 20CrhmTi, 5CrhmMo, etc. Workpiece diameter range: diameter 20mm~500mm

Product Detail

Application Video

Product Tags

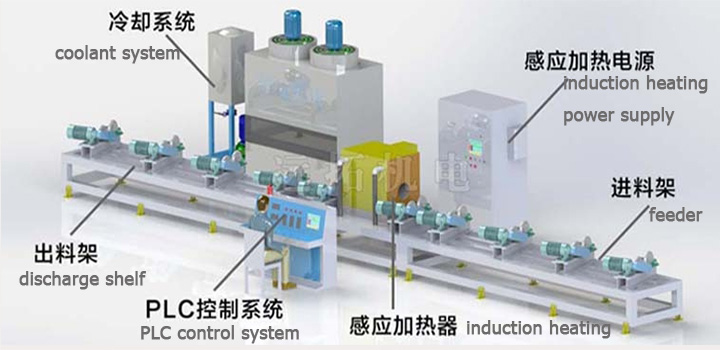

Thick wall steel tube annealing machine adopts a medium frequency heating device, which has the advantages of low power consumption and high production efficiency. In response to the characteristics of heating during motion and the heated workpiece being thick walled steel pipes, special design should be made for the parameters of the series induction heating power supply and inductor in the system design. The entire thick walled steel pipe annealing equipment system adopts a separate series resonant medium frequency induction heating power supply control.

Features:

Product name: steel tube induction annealing machine

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304316, 20Cr, 40cr, 20CrIo, 35CrIo, 42CrHo, 40CrNIMIO, GCr15, 651m, 501m, 50Cr, 3Cr2w8v, 20CrhmTi, 5CrhmMo, etc. Workpiece diameter range: diameter 20mm~500mm

Workpiece length range: greater than 2m

Intelligent intermediate frequency power supply series: KGPS160KW-8000kw

Power consumption: calculated based on the customer’s workpiece material and diameter, heating temperature, operating speed, etc.

The medium frequency thick walled steel pipes induction annealing equipment is composed of a PLC and a human-machine interface, which has a convenient management system. It has a strict management system with fully digital and high depth adjustable parameters, a complete one click restoration system, and can provide corresponding language switching according to different countries and regions. Simple and easy to operate.

The conveying roller of the annealing equipment for thick walled steel pipes: The axis of the roller forms an angle of 18-21 ° with the axis of the workpiece, and the workpiece moves forward at a constant speed while self transmitting, making the heating more uniform. The roller conveyor between the furnace bodies is made of 304 stainless steel and water-cooled. The annealing equipment for thick walled steel pipes has no radiation to the human body. The operation is simple and can be learned in a few minutes.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.