Steel bar induction hardening furnace

Features:

Application: Hardening & Quenching

Material Heated:High speed steel, 45#, stainless steel

Bar Diameter Allow: Φ20-110mm

Product Detail

Application Video

Product Tags

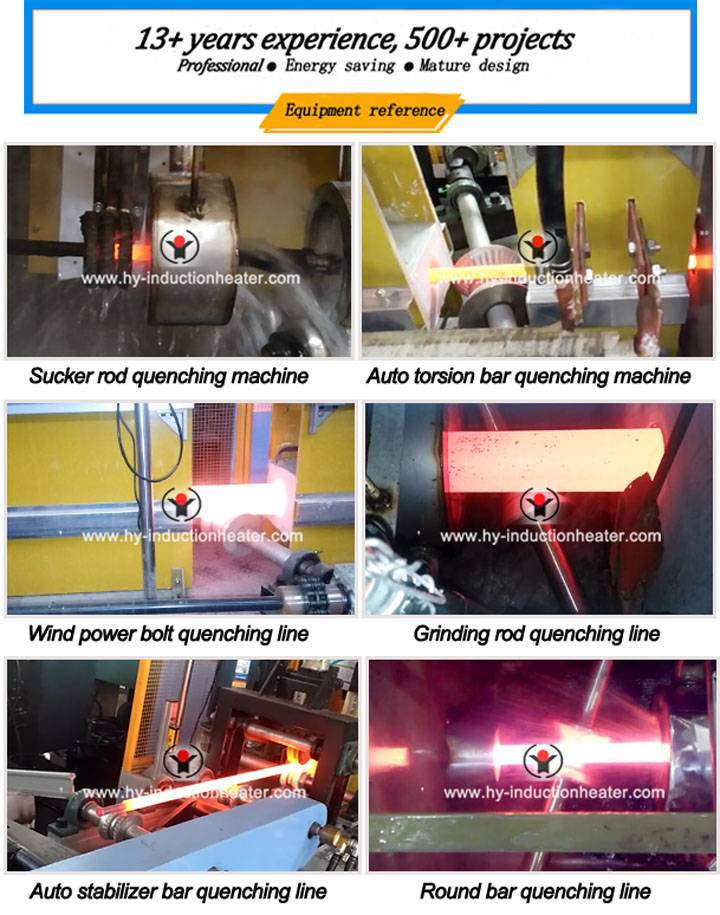

Forever has nearly 13 years of experience in the field of steel bar hardening furnace and our steel bar hardening furnace has been proven successful operation in user’s plant. The entire design and production will be completed in our factory.

Steel bar hardening furnace is applied to

| ● Stainless steel | ● Plate |

| ● Steel bar,round bars | ● Spring |

| ● Octagonal hammer | ● Seamless pipe,thick-walled pipe |

| ● Casing, tubing | ● Steel wire,steel strand |

| ● Rebar, deformed bars | ● Bearing steel |

| ● Rod | ● Gear,roller |

Steel bar hardening furnace advantages

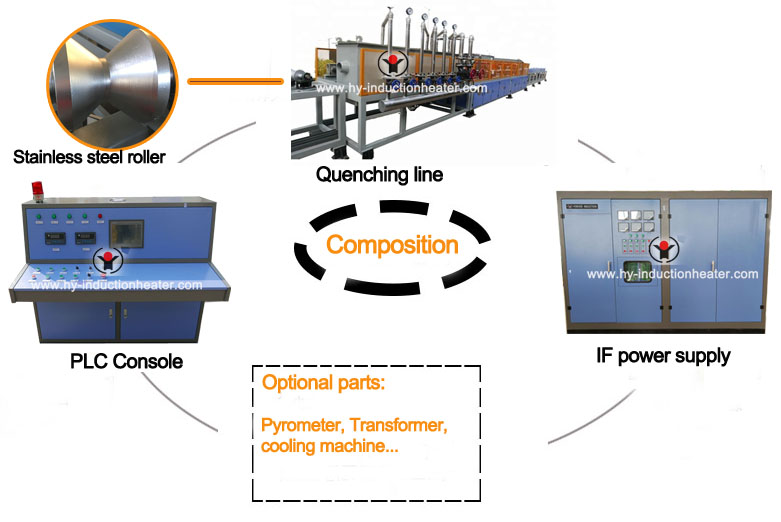

● Uniform heating: The angle between roller axis and bars axis is 18 ~ 21 °. The bars is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● Uniform cooling:To meet the requirements of different hardenability, spraying system adopts multi-level spray cooling and the pressure & flow in water spray ring at all levels is adjustable.The bars will be placed in the middle of spray ring to ensure uniform pressure and flow. So the bars needn’t straightening after induction heat treating with our line. The surface hardness difference is very small, which is only HRC3.

● Closed-loop temperature control system: Our engineer will set the process parameters in the system, and when the heating temperature is too high or too low, the system will adjust the temperature to the required temperature through adjusting power.

● ”One key” operation: The engineer will set the required process as per user’s production requirement.For example, when the user need to do heat treatment for ø30mm, the operator can choose the corresponding recipe and start, then the system will run as ø30mm process parameters. This function makes the operation more easier and doesn’t need the operator to master professional skills.

● More flexible: When your production plan don’t have too much, you can reduce the speed of bars running, then it will need less than. This is very flexible for the production plan.

Service for steel bar hardening furnace

● Factory Inspection

● Free technical training and after-sale service.

● Warranty period: 12 Month

● Working life: More than 10 Years

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.