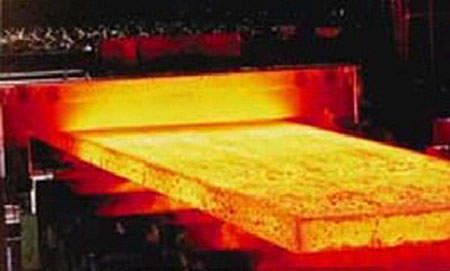

Steel Plate leaf spring forging heating furnace

Features:

Application: Forging & Forging

Material Heated:Carbon Steel & Alloy Steel

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product name:Plate forging furnace

Heating way:Induction heating

Control way: Siemens PLC

Forever plate forging furnace is used for plate or sheet heating before forging with accurate temperature control & energy saving power supply cabinet. We can not only supply quality plate forging furnace but also our engineer will give the best solution for plate forging furnace.

Generally speaking, plate forging furnace is composed of converter, electric capacitor, induction heater, loading device, feeding device, discharging device and temperature measuring equipment. When it is in the state of automatic control, it also includes PLC programmable controller, HMI human-machine interface or industrial control computer system and industrial control configuration software and various types of sensors. There are four main types of lining materials for steel plate forging furnace: silicon carbide, white corundum, stainless steel and integral tying; the appropriate one will be selected according to the purpose and structural characteristics.

Induction mass heating for plate forging

● Available for both Ferrous & Non-ferrous applications

● Rapid heating of Round or Square billets and bars.

● Homogeneous through heating

● Minimized scale loses

● Facility for easy starting & stopping of the heater

● Steady billet through put under uniform conditions.

● Space economy in installation

● Clean working atmosphere.

● Semi or fully automatic operation through PLC

● Optional computerized data logging.

Technical Support for plate forging furnace

● Powerful after-sale service team.Our engineer will go to your plant to help you install and debug the induction heating equipment.

● With excellent technical instruction,we can ensure the reliability of induction heating process and final product qualification rate.

● In order to analysis failures and supply spare parts,the users can contact with us on telephone or internet.

● Important accessories stored in our warehouse, we can supply t accessories at any time.

●Provide the tool matching with the offered production equipment such as converter, SCR etc.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)