Induction billet heater

Features:

| Application | Steel billet heating before hot rolling |

| Power | 100KW-8000KW |

| Non standard | Professional customization |

| Temp.control | Infrared thermometer |

Product Detail

Application Video

Product Tags

Product Name: Induction billet heater

Typical application:

Forever manufacture and supply a wide range of induction billet heater for billet forge heating and rolling heating applications. Our induction billet heater has realized automatic and inline heating before billet charging into rolling mills. Usually, our induction billet heater can heat the billet temperature from 700-800℃ to 1050-11200℃ to meet production requirements.

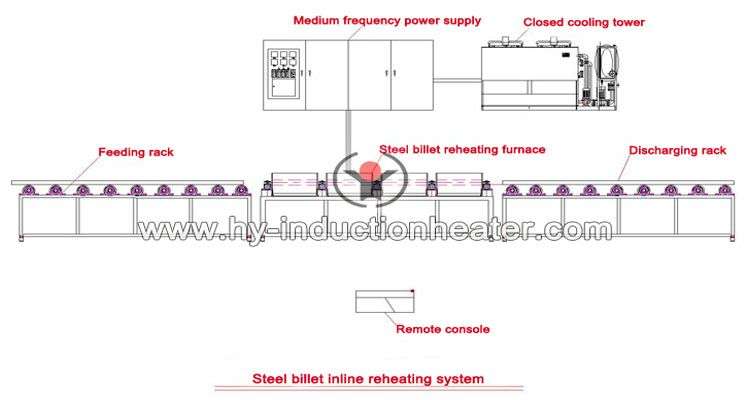

Induction billet heater working layout

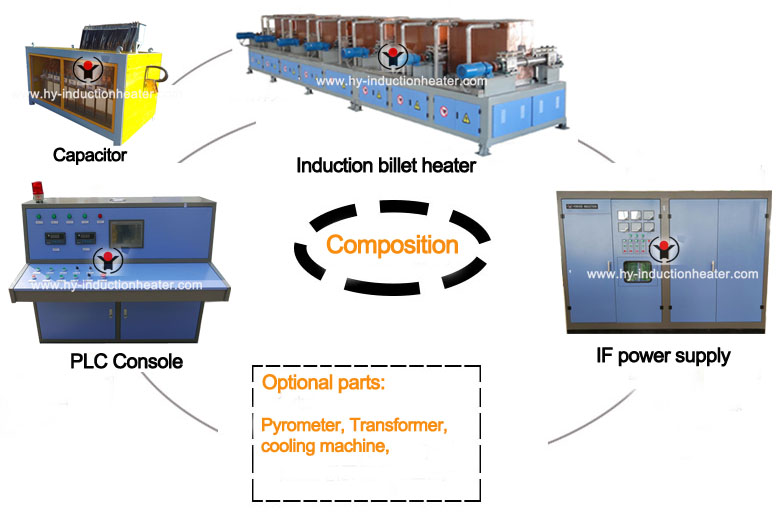

Induction billet heater main component

● Medium frequency power supply

● Induction billet heater : Designed as per billet size and capacity

● Capacitor

● Remote control box

● Infra Red Pyrometer

Advantages of induction billet heater

● High efficiency, precious induction heating.

● Proven and mature design

● No preheating time,100% successful start rate.

● Automatically store technical parameters,allow for inquiry,print.

● Heavy Duty Construction, for toughest forging conditions

● After-sales service: professional engineer will help to install and debug the billet induction heating equipment.

Forever induction billet heater features

● Digital phase-locked: digital phase-locked technology to achieve automatic frequency tracking, which can automatically adapt to various inductors.

● Modular design: drive module control to ensure the reliability and easy maintenance of billet heating equipment.

● Resonance frequency conversion technology: Resonance frequency conversion technology makes the overall efficiency of the equipment more than 90%, high efficiency, energy saving, power consumption is only 20% – 30% of the tube induction heating equipment.

● Reasonable induction heating coils design, which can achieve the Max. heating efficiency for billet heating and can work for 24 hours continuously.

● The induction billet heater adopts the PLC control program of human-machine interface, which is fully automatic and intelligent.

● The heater is controlled by air-cooled power supply. The power consumption is low and the power supply can move freely without using water.

| Bar Diameter | Bar Length | Heating Temp. | Production capacity |

| Φ36-45mm | 1500mm | 1125°C ± 25 | 3T/H |

| Ø60mm | 6000mm | 1200℃ | 4.4T/H |

| Ø70mm | 6000mm | 1200℃ | 5.3T/H |

| Ø80mm | 6000mm | 1200℃ | 6T/H |

| Billet size | Billet length | Heating Temp. | Production capacity |

| 60*60mm2 | 3m-4 m | 1000℃-1100℃ | 25T/H |

| 75*75mm2 | 3-6 m | Room Temp.-1100℃ | 25T/H |

| 100*100mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 120*120mm2 | 750℃-1100℃ | 30T/H | |

| 120*120mm2 | 11.5-12.5m | 950℃-1150℃ | 90T/H |

| 125*125mm2 | 6 m | Room Temp.-1200℃ | 8T/H |

| 125*125mm2 | 2 m | 750℃-1000℃ | 7T/H |

| 130*130mm2 | 6 m | 950℃-1150℃ | 50T/H |

| 135*135mm2 | 6 m | 950℃-1150℃ | 100T/H |

| 150*150mm2 | 11.5-12.5m | 950℃-1150℃ | 70T/H |

Related product: Billet induction heater billet induction heating Steel billet hot rolling

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.