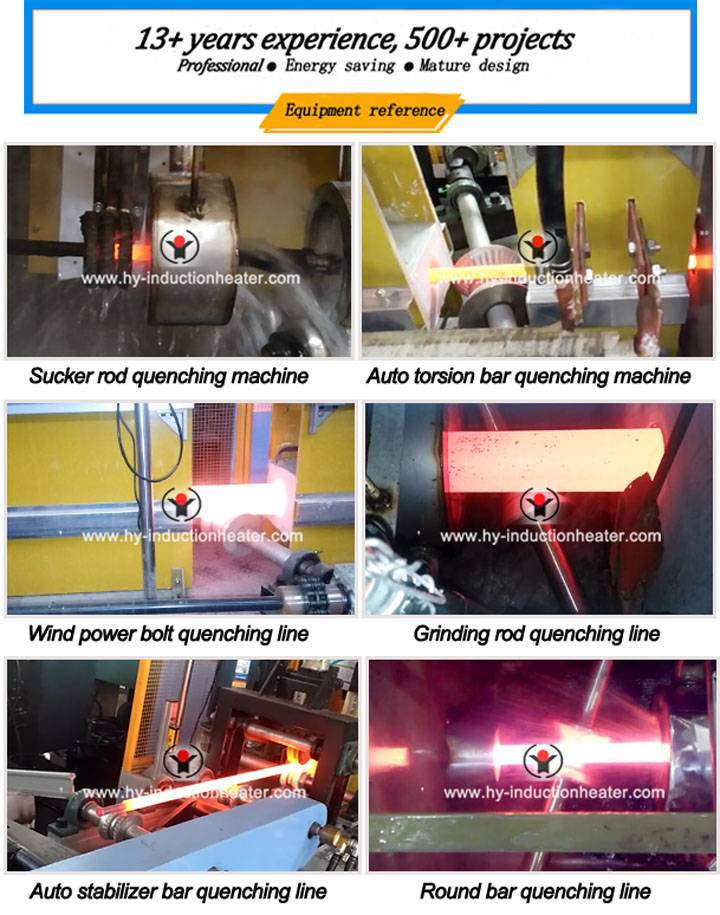

Sucker rod heat treatment line

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Heating way: Induction heating

Product Detail

Application Video

Product Tags

Sucker rod heat treatment line

● Product Name:Sucker rod heat treatment line, Sucker rod hardening and tempering furnace

● Diameter range: Ø16, Ø19, Ø 22, Ø25, Ø32 mm

● Length: 7520~9100 mm

● Quenching depth: 1.1~2.3mm(Or the quenching depth reach to 5%~13% of sucker rod body)Surface hardness after quenching is HRC≥42.

● Productivity: 18 pcs/hour

This is the second sucker rod induction heat treating equipment for the same China customer. Two years ago, they ordered the sucker rod quenching line from us. The feedback is very good, so now they ordered another line.

Sucker rod heat treatment line working process::

Manual feeding→automatic turning sucker rod→Transmission→quenching heating→Spraying→Sucker rod receiving.

Except the need for manual feeding, other processes are all automatically completed by PLC control and the entire process of production will be recorded.

Sucker rod heat treatment line design introduction

● The sucker rod is going through on the roller while rotating( roller has function to avoid rod head automatically)

● In order to ensure the rotation speed of sucker rod in transmission process, the transmission device is controlled by our CNC control system developed by ourselves.

● In order to reduce rod deformation,we installed pinch rollers on both sides of inductor. At the same time, this design will avoid rod end.

● PLC controlled for heating & transmission; avoid threaded part heating automatically

(automatically adjusting rotation speed, transmission speed and heating power) ensuring more uniform quenching.

● Based on the above requirements, we design the power is 200KW, frequency is 30000Hz, actual working frequency is about 20000Hz.

Advantages

● High reliability:Adopt famous brand components of IGBT power supply which reduce fault rate and make sure the equipment can run reliably.

● Safe and reliable.There are reliable protection covers for the mechanical rotating parts,which is durable and very safe for operators. Automatic protections for water temperature,water pressure,phase shortage, overcurrent and undervoltage.

● Easy installation & commission and simple operation.

● Transmission mechanism frame has sufficient strength and rigidity for ease of installation of equipment

● Feeding and discharging table is using high quality steel welded firmly, which can withstand a certain impact load.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.