Steel Pipe Induction Annealing Equipment

Features:

Product Detail

Application Video

Product Tags

Product Name: Steel pipe induction annealing equipment

Workpiece materials: Q195, Q235, 10, 20, 35, 45, 304, 316, 20Cr, 40Cr, 20CrMo, 35CrMo, 42CrMo, 40CrNIMO, GCr15, 65 Mn, 50Mn, 50Cr, 3Cr2W8V, 20CrMnTi, 5CrMnMo, etc.

Workpiece diameter range: 10mm to 406mm in diameter

Workpiece length range: greater than 2m

Intelligent intermediate frequency power supply series: KGPS160KW-8000kW

Power consumption: calculated based on the customer’s workpiece material and diameter, heating temperature, operating speed, etc.

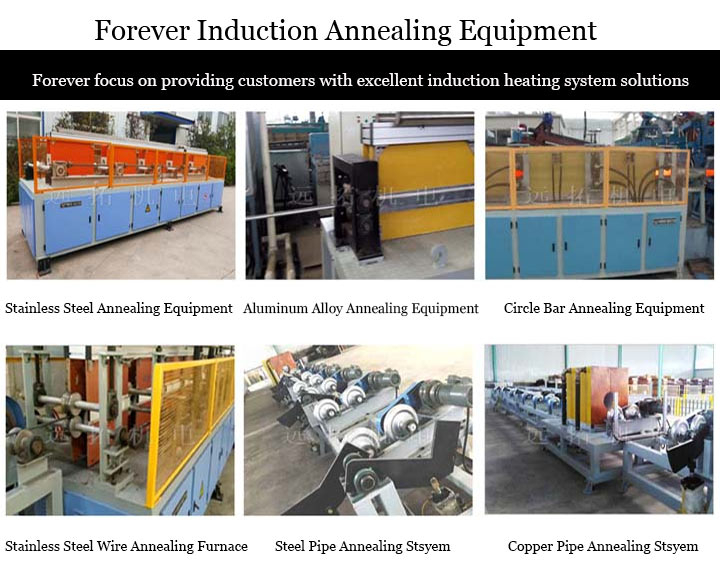

Hebei Forever Heat Treatment Annealing Equipment Manufacturer, specializing in the production of steel pipe annealing equipment, pipe annealing furnace, steel pipe induction annealing equipment, round pipe induction heating equipment, steel pipe continuous annealing furnace, bar annealing furnace, etc. Forever’s steel pipe medium frequency annealing equipment is efficient, energy-saving, environmentally friendly, reliable, and has been an old manufacturer for many years with exquisite technology. We choose steel pipe annealing equipment from Forever Electromechanical, and all employees of Forever are dedicated to serving you.

The working principle and purpose of Induction annealing steel pipe machine:

Steel pipe annealing is a heat treatment method that heats steel pipes to a temperature where phase transformation or partial phase transformation occurs, and then slowly cools them after insulation. The purpose of using medium frequency annealing equipment for steel pipes for annealing is to eliminate structural defects, improve the structure, homogenize the composition, refine the grain size, enhance the mechanical properties of the steel, and reduce residual stress; At the same time, it can reduce hardness, improve plasticity and toughness, and improve cutting performance. So annealing is not only to eliminate and improve the structural defects and internal stresses left by the previous process, but also to prepare for subsequent processes. Therefore, annealing belongs to semi-finished product heat treatment, also known as pre heat treatment.

The working principle and purpose of steel pipe annealing equipment:

Steel pipe annealing is a heat treatment method that heats steel pipes to a temperature where phase transformation or partial phase transformation occurs, and then slowly cools them after insulation. The purpose of using medium frequency annealing equipment for steel pipes for annealing is to eliminate structural defects, improve the structure, homogenize the composition, refine the grain size, enhance the mechanical properties of the steel, and reduce residual stress; At the same time, it can reduce hardness, improve plasticity and toughness, and improve cutting performance. So annealing is not only to eliminate and improve the structural defects and internal stresses left by the previous process, but also to prepare for subsequent processes. Therefore, annealing belongs to semi-finished product heat treatment, also known as pre heat treatment.

Contact person: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)