Short bar quenching tempering furnace

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Diameter range: ø10-120mm

Heating way: Induction heating

Product Detail

Application Video

Product Tags

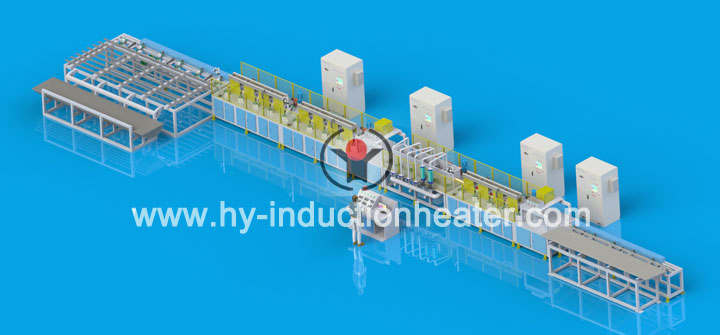

Short bar quenching tempering line

● Product name:Short bar quenching tempering line, Short bar induction heat treating line

● Diameter range: ø10-120mm

● Product strength: Rapid quenching & tempering speed, less oxidation, uniform quenching & tempering,energy saving

● Cooling way: Spray cooling

Short bar quenching tempering line is suitable for induction quenching and tempering of various shaft parts. The machine consists of a machine body, power supply, loading & unloading device,inductor for quenching, inductor for tempering cooling system and other components.Controlled by PLC system, the system has to function of automatic feeding, heating, parameter monitoring and recording etc..

Configuration

● High strength welded machine body,fine maching after aging treatment , stable performance.

● Motor for feeding bars: frequency control.

● Temperature measurement: Online temperature measurement for quenching heating temperature and tempering temperature, temperature closed-loop control can be achieved.

● Inductor replacement: manual.

● Adjustable inductor matching.

● Alarm: sound / light fault alarm, alarm and record display on control interface

● Connection for inductor and sprinkler cooling interface: stainless steel / Brass quick change joint.

● Electronic control mode: PLC/ touch screen +PLC simple CNC.

● The machine control system has function of various process parameters monitoring and record, historical inquiry, online monitoring and output printing.

● Loading & unloading: fully automatic loading and unloading mechanism

Features & control system of intelligent induction heating power supply

● Parallel resonance design, phase-shift control; mature and stable performance; more advantages for the power of 3000KW or above.

● DSP control, start with instant capture & Phase-Locked, meet the requirement of frequent start and stop ; 100% successful start rate.

● Self-Adaptive at frequency variation or load variation;the frequency adaptation range is 200-10000Hz; induction furnace replacement is automatic matching, no need to make any manual adjustments.

● The power supply cabinet adopts T2 copper which is processed by sandblasting and passivation; low leakage inductance, antioxidant, effectively reducing line losses.

● Full touch screen control, pure digital setting, with complete process record and strict purview control.The main parameters can be one key recovery of the factory settings.

● Per single output power 50 ~ 6000KW, frequency 200 ~ 10000Hz

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.