Seamless pipe hardening and tempering furnace

Features:

Application: Hardening & Tempering, Solution

Material Heated:Carbon steel 45#,40Cr,42CrMo,65Mn

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

seamless pipe hardening and tempering furnace

Heat treatment is very important because through heating, pipes could have much better physical and mechanical properties for all application of pipes, no matter stainless pipe, seamless pipe, ERW pipe or welding pipe.

Forever, as an induction heat treatment furnace factory in China, can provide you with quality seamless pipe heat treatment line with economic proposals.

Seamless pipe heat treatment Technical requirement

● Steel pipe type : seamless pipe

● Seamless pipe size: Ø (304mm) * 8000 mm wall thickness 4mm;

Ø (406.4mm) * 8000mm wall thickness 15mm;

● Production process: solution heat treatment

● Quenching temperature: Design as per specific material and heat treatment requirements,usually about 1100 ℃

● Heating efficiency: Ø (254mm) * 8000 mm wall thickness 4mm tube ———-600mm/min

Ø (406.4mm) * 8000 mm wall thickness 15mm tube ——250mm/min

Equipment configuration and workflow

Storage rack → conveying device → power supply cabinet → Remote console → induction heating → water quenching → discharging device → receiving rack

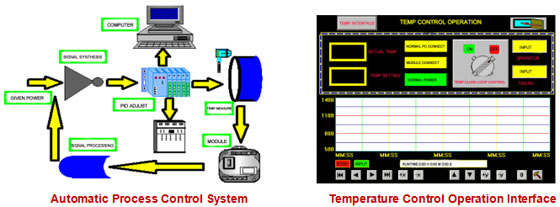

Seamless pipe heat treatment Automatic system

● Mechanical system: The whole system is automatic feeding–automatic transportation–automatic heating–automatic discharging.During the whole process, only need worker to put work piece on the storage rack.

● Control system: Automatic and accurate closed temperature control system, which is very important for seamless pipe heat treatment process because the seamless pipe need uniform heating during the heat treatment process.

Successful cases

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heating equipment is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.