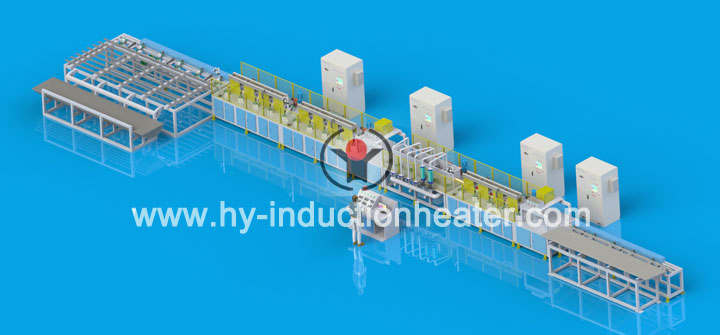

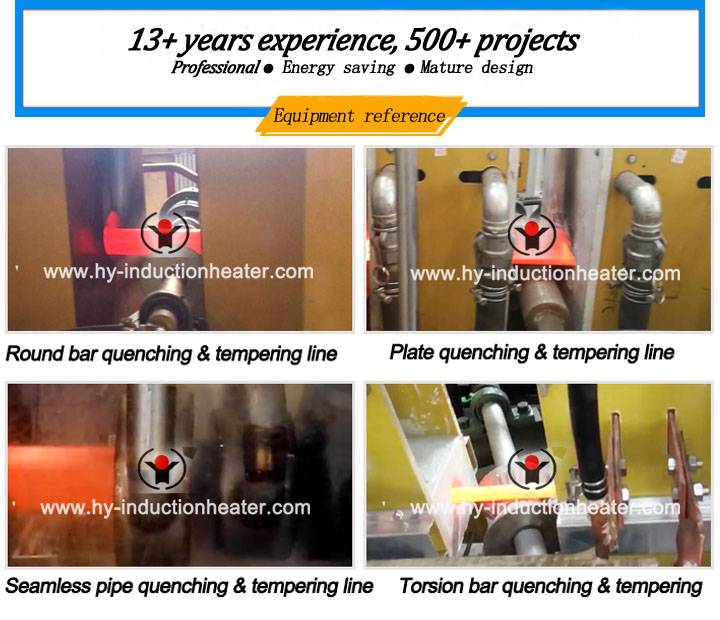

Quench and temper line

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Heating way: Induction heating

Product Detail

Application Video

Product Tags

● Product name:Quench and temper line for bar, pipe, tube, plate

● Bar diameter : ø10-120mm

● Pipe diameter: Not limited

● Application: Used for heat treatment for long bar, tube, casing, suction rod, drill pipe, plate, blade etc.

Quench and temper line advantages

● Accurate temperature monitoring & control.

● Inverter efficiency of 92%

● Full programmable speed control for all material handling devices

● Fully automated quick-change lines available

● Recipe driven algorithms enable low quantity orders and small batch processing

● Automatic induction coil change-over when required

● Instant on/off capability with induction heating equipment

● Optional upset end preheating stations

● Optional infrared camera upgrades

● Capable of seamless and welded tube processing

● Wide variety of materials can be processed from low-carbon steel to martensitic stainless steels

● Software diagnostics provide specific troubleshooting assistance for maintenance technicians

● Local service and spare parts available worldwide

Features for quench and temper line

● Transmission roller table: The angle between roller axis and work piece axis is 18 ~ 21 °. The work piece is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● Roller table group: Independent control for feeding group, inductor group and discharging group,which is beneficial to continuous heating to avoid work piece gap.

● Temperature closed-loop system: Both hardening and tempering process used closed-loop control system which consists of America Raytek infrared thermometer and German Siemens S7 with high precision temperature control.

● IPC system: Powerful functions including the display of the current working parameters status, work piece parameters memory, storage, print, fault display and alarm and so on.

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.