Medium frequency heat-treating equipment

Features:

| Material | Carbon steel, alloy steel |

| Suitable for | Bar,pipe,tube,plate,billet |

| Process | Quenching, tempering, annealing |

Product Detail

Application Video

Product Tags

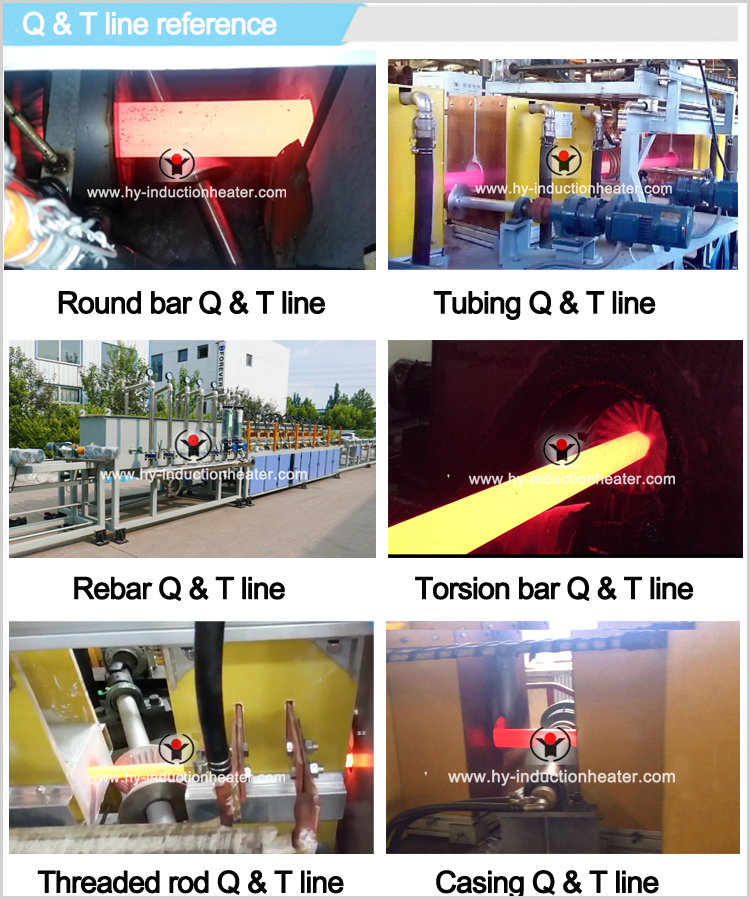

Forever professional customized medium frequency heat-treating equipment has features of quality assurance, factory direct sales and reasonable prices. Our medium frequency heat-treating equipment has widely used for torsion bars, grinding bars, wind power bolt, steel pipe, plate and so on. Using the new generation IGBT power module and advanced frequency conversion technology to control the entire System, Yuantuo medium frequency heat-treating equipment has got good reputation from our customers.

Basic information for medium frequency heat-treating equipment

| Material | Carbon steel, alloy steel |

| Length | ≥2000mm |

| Suitable for | Bar,pipe,tube,plate,billet |

| Efficiency | Customized |

| Process | Quenching, tempering, annealing |

Medium frequency heat-treating equipment characteristics:

● Provide remote console with touch screen or IPC system according to user requirements.

● Customized human-machine interface and highly user-friendly operation instructions enable one person to operate the entire medium frequency heat-treating equipment, saving labor and expenses.

● All-digital, high-depth adjustable parameters, as long as you input workpiece steel grade, size, then the induction heat treating furnace will call the relevant parameters automatically without manually record, consult and input. It has high accuracy history curve function. U disk or network backup, data can be stored for a long time.

●Strict grade management system for medium frequency heat-treating equipment. The equipment is equipped with a one-click restoration system. (If a problem occurs in the adjustment, or you want to restore the device to its original state, you can restore the original data by pressing a button.)

Remote console advantages

The system can record, save, inquiry and print the production parameters including heating temperature, production capacity and power supply running parameters etc. According to technical requirements, the system will automatically record and analysis the parameters changes and predict fault and alarm. Remote control the whole system and automatically generate various reports to achieve the traceability of the production process.

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(bar) | PLC Control | IGBT200KW Hardening |

| Ø30-Ø70mm( bar) | PLC Control | KGPS350KW Hardening |

| Ø80-Ø110( bar) | PLC Control | KGPS450KW Hardening |

| Ø16-Ø32 mm(rod) | PLC Control | IGBT200KW Hardening |

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.