Induction pipe heating furnace

Features:

Application: Forging , Rolling, Annealing & Quenching

Heating : Pipe, Tube, Pipeline

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

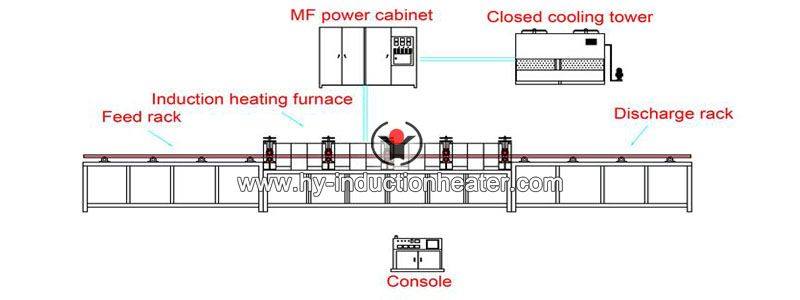

Steel pipe heat treatmeant furnace

Our Steel pipe heating furnace is designed & manufactured as per user’s specific requirements with full automatic system using PLC & digital display.

Induction heating is an accurate, fast, repeatable, efficient, non-contact technique for heating metals or any other electrically-conductive materials.

Induction pipe heating furnace is suitable for

● Pipe diameter: ø20-300mm

● Pipe length: Not limited

● Power required: As per your production capacity

● Temperature control: Temperature automatic adjustment

Features for induction pipe heating furnace

● Manual, semi-automatic and automatic systems

● Optional automatic loading and unloading

● Optional temperature continuous control and monitoring system

● Fast heating, low scale, high temperature uniformity

● Easy exchangeable inductors

● Power 100KW- 8000KW

● PLC controlled

Inductor manufacturing process:

The ratio of inductor inner diameter and the bars outer diameter is within a reasonable range, which is designed as per user’s parameters given. Our inductor heating coils are made with large T2 rectangular copper tubes after annealing heat treatment, pickling, water pressure test, baking, mica tape, glass ribbon double insulation, drying, knotting and assembling process. The inductor will be a Cuboid after finishing. It has good features of vibration and Entirety.

There is copper plate to protect at the both end of inductor and it cancan effectively prevent electromagnetic radiation damage to the operators.

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heater is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating fiel