Steel pipe heat treatment equipment

Features:

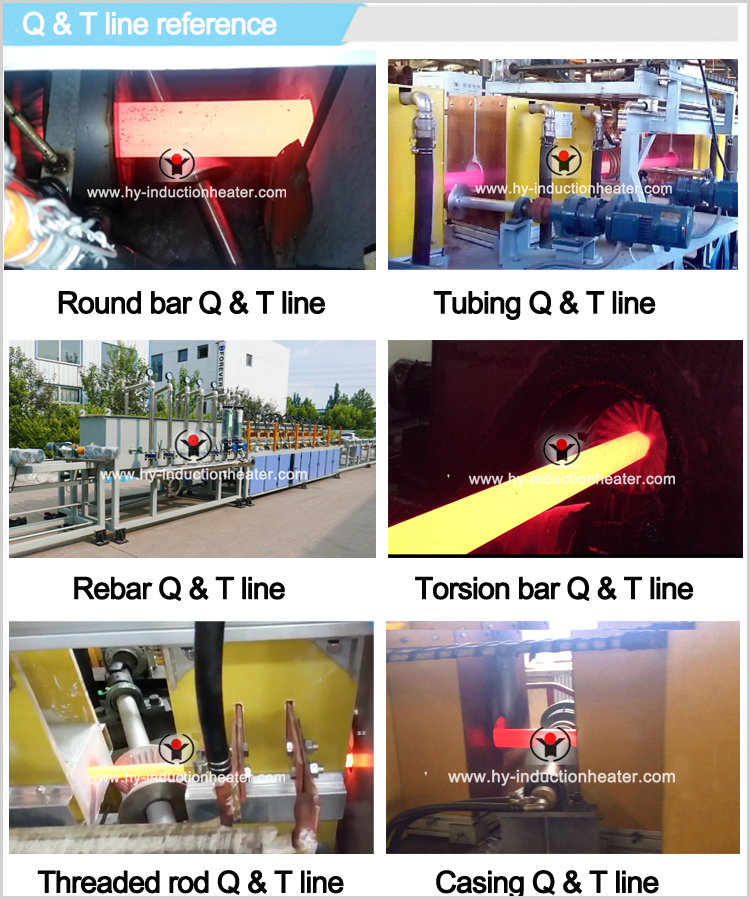

Application: Hardening ,Annealing & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Pipe Diameter Allow: Φ60-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

steel pipe induction heating furnace

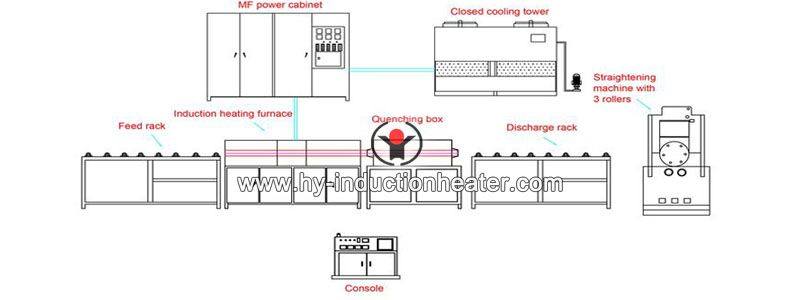

Heat treatment is a process of improving performance of metal material and products. According to different purposes, the materials and the workpiece is heated to the proper temperature, thermal insulation, followed by cooling in different ways, changing its internal organization in order to get the performance you require. Steel pipe heat traetment usually include annealing, normalizing, quenching, tempering, chemical heat treatment etc.

We will design and build a high-quality, fully automated induction heating solution within your budget that maximizes your output and remains energy efficient.

Steel pipe heat treatment equipment advantages

- High efficiency

- Proven & mature Design

- Reduced customer start up time

- Advanced PLC control, power & temperature control

- Quick release connections for both power & water

- All the cables and capacitors are well protected for long life performance

Our service for Steel pipe heat treatment line

● Pre-sale service:

- Recommend the most suitable induction heating equipment for customers, according to their requirements.

- Inquiry and consulting support.

- Sample testing support.

- View our Factory.

● In-sale service:

- Strictly manufacture the induction heating machine, according to relevant technical standards.

- Take run test, according to relevant equipment test run regulations.

- Strictly check up the machine, before delivery

- Delivery on time.

● After-sale service:

- 12 months warranty period

- Within one year free warranty, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, Forever shall provide replacement parts after detecting the faults.

- If any big quality problems occurs out of the guarantee period, Forever will send maintenance Technician to provide visiting service after checking with the customer and charge for a favorable price.

Successful cases for steel pipe heat treatment line

| Pipe diameter | Automatic control | Power design |

| Ø95,Ø114 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø73.2,Ø88.9,139.7 mm(Drill pipe) | IPC Control | KGPS500KW Quenching+KGPS100KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-Ø110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at sales@foreverfurnace.com for more detailed price & solution !