Induction heating steel bar

Features:

Application: Forging , Forging , Rolling & Quenching

Material: Carbon steel, Brass,Iron,Alloy steel,Stainless steel,Aluminum

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product name:Induction heating steel bar furnace

Forever is a leading manufacturer of induction furnace for induction heating steel bar with advanced induction heating technology and powerful service team. We are dedicated to providing our customers with superior induction heating steel bar furnace.

Induction heating is efficient, easily controlled, uses no energy when not heating, and puts the heat where you want it, when you want it. No idle time, no massive refractories to heat, and close coupling enables you to use energy in the best possible way.

Applications

- Forging & forming: Suitable for rod, pipe, plate, slab, billet, auto parts, fasteners

- Surface quenching: Suitable for Shaft, long bar, long pipe, sucker rod, drill pipe, drill rod

- Annealing: Suitable for Tube, pipe, pipeline, copper pipe

- Hardening & tempering: Suitable for Drill pipe, drill rod, piston rod, bolt, shaft

- Special application: Bar heating used for forging steel balls, rolling steel balls.

Benefits

- High -efficiency solid-state power units

- Standard units available in frequencies between 60 Hz and 10000 Hz

- Dual frequencies available for pre and post Curie heating

- Modular design for quick coil change to accommodate for different sizes

- PLC control;closed-loop temperature control

- Fully automated, PLC controlled material handing system

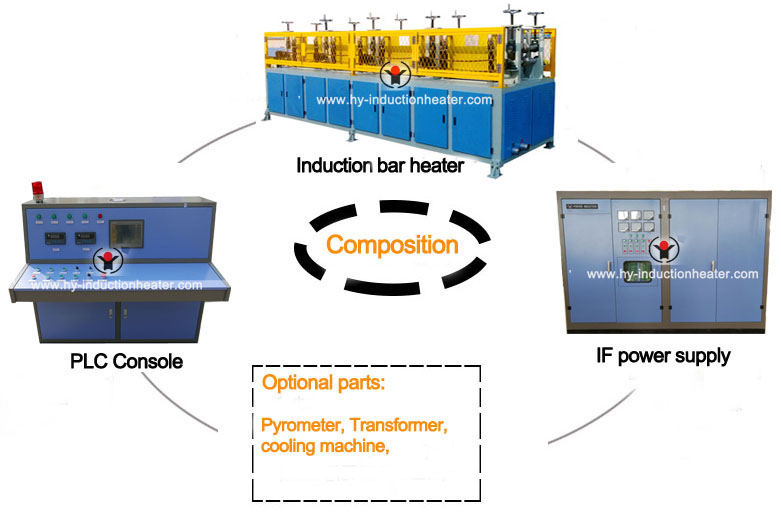

The main features of the induction heating furnace for steel bar

1. Fast heating speed, less oxidation decarbonization due to the principle of medium frequency induction heating for electromagnetic induction, the heat will produce inside the steel bar. Because of the fast heating speed of the heating method, it has little oxidation.

2. It can realize full-automatic unmanned operation by selecting automatic feeding and automatic discharging separated checking device and matching with our company’s special control software.

3. Uniform heating from the sruface to the core, from the head to the tail and the temperature tolerance is ±10℃, which can reduce the damange to the forging die and the power sumption.

4. Compared with other heating methods, induction heating with low energy consumption and pollution-free has the advantages of high heating efficiency, low energy consumption and pollution-free.

Successful cases

| Bar Diameter | Bar Length | Heating Temp. | Production capacity |

| Φ36-45mm | 1500mm | 1125°C ± 25 | 3T/H |

| Ø60mm | 6000mm | 1200℃ | 4.4T/H |

| Ø70mm | 6000mm | 1200℃ | 5.3T/H |

| Ø80mm | 6000mm | 1200℃ | 6T/H |

| Diameter | Automatic Control | Power Design |

| Ø18-Ø28 mm(Steel bar) | PLC Control | IGBT200KW Quenching |

| Ø30-Ø70mm(Steel bar) | PLC Control | KGPS350KW Quenching |

| Ø80-Ø110(Steel bar) | PLC Control | KGPS450KW Quenching |

| Ø16-Ø32 mm(Sucker rod) | PLC Control | IGBT200KW Quenching |

As our induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for more detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.