Hardening and tempering is one of heat treatment process, which is using induction heating method and water cooling. With more than 13 years’ experience, Forever is very familiar with heat treatment process for different material, such as 45#, 40Cr, 42CrMo, 65Mn. For different material, the internal structure will have changes at different temperature to make the workpiece performance meet different requirements.

Forever hardening and tempering line has widely used in the following industries:

● Mining machinery: Single prop, long metal beam, U type steel frame, type beam, grinding rod, bulldozer blade

● Auto parts industry: Stabilizer, leaf spring, torsion bar

● Petroleum machinery industry: Drill pipe, drill collar, sucker rod, tubing, casing, seamless pipe, weld pipe

● Wind power industry: Wind turbine bolt, anchor bolt

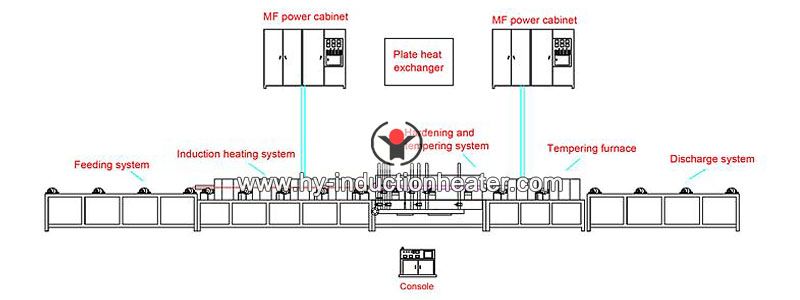

Hardening & tempering process

Successful cases:

Mining grinding rod hardening and tempering production line

● Power supply system: KGPS 160 KW-1000 KW/0.5-2.5 KHz.

● Transmission roller table: The angle between roller axis and work piece axis is 18 ~ 21 °. The work piece is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● Temperature closed-loop system: Both hardening and tempering process used closed-loop control system which consists of America Raytek infrared thermometer and German Siemens S7 with high precision temperature control.

● The power consumption is 280-320 KW/H with hardening and self-tempering mode.

Oil drill pipe/rod hardening and tempering Line

● Power supply composition : Hardening 500KW / 1000HZ Tempering 200KW / 500HZ

● Feeding system: Independent motor reducer drive for each axis , independent inverter control; flexible design speed differential output, section speed control.

● Powerful recipe management system for induction heating equipment–after inputting parameters of steel grade, outer diameter and wall thickness, this system can automatically call the relevant parameters, no need to manually record, check, input required parameters for various work piece.

Engineering machinery blade plate quenching Line

● Power supply system:KGPS 200~800 KW/4~8 KHZ or IGBT 200~800 KW/4~15 KHZ.

● Feeding system: Roller table+power double pitch, independent motor reducer drive for each axis , independent inverter control; flexible design speed differential output, section speed control

● The power consumption is 240-260 KW/H for heating each ton of steel to 840℃.

Bar & pipe hardening and tempering Line

● Power supply system: KGPS 160 KW-1000 KW/0.5-2.5 KHz.

● IPC system: Powerful functions including the display of the current working parameters status, work piece parameters memory, storage, print, fault display and alarm and so on.

● The power consumption is 280-320 KW/H with hardening and self-tempering mode.