Supporting parts & systems

With our Temp.control device, you can see the precious temperature on the LCD.This device will form Temp.closed-loop control with our power supply cabinet. If the temperature exceeds the setting temperature, the power supply cabinet will automatically adjust power output to make sure the temperature can be controlled to normal range.

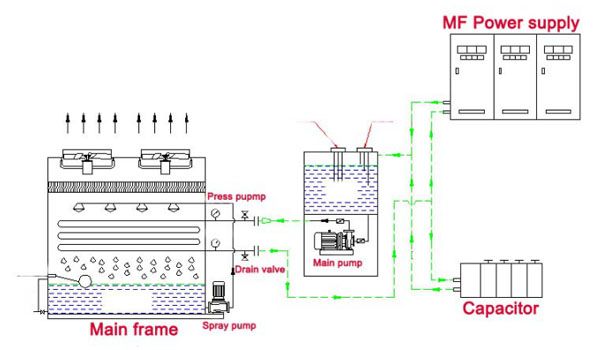

Water cooling system

Cooling system is very important for the complete induction heating system, which can have effect on the service life of induction heating equipment. Plate heat exchange cost is small, but it need a water pool, and it is used for small power induction heating machine.

The pure water circulating cooling system is also called water cooling tower.It does not need a water pool.And it can cool the complete induction heating system including power supply unit & induction heater with long service life.

Working principle:The soft water from induction heating equipment will flow into the entrance of cooling tower and flow in the closed red copper tube.The heat is absorbed by the tube wall and the water is discharged out of the tower by top fan motor. The recycled water after the temperature drop will flow into heating equipment for use.At the same time,the spray system help to give off heat.

The features:The soft water closed recirculating doesn’t contact with air to avoid scaling, blocking phenomenon and Electrolysis phenomenon due to water quality problem; Fan motor+coil+spray(Three treble cooling) the cooling effect is good;Do not need to make pool;Easy to move and save space.

Do not inject water before installing equipment. You can use the cooling tower after installing and connecting(About 100 kgs).