induction heating furnace for forging

Features:

Application: induction heating

Workpiece: rod ,steel bar

Length Allow:Not limited

Product Detail

Application Video

Product Tags

FOREVER Electrical and Mechanical Equipment Manufacturing Co., Ltd. is a professional design and manufacture enterprise of induction heating furnace for steel ball, which integrates scientific research and production. The quality of steel ball induction heat treatment furnace, the main product of forever Electrical and Mechanical Co., Ltd., has achieved excellence and can stand the test of different users. Welcome to the production inspection and guidance, discuss the steel ball heating and heat treatment equipment business.

Process flow and description of steel ball induction heat treatment furnace:

Steel bar inspection: Mainly inspect straightness and surface crack;

Feeding: Generally, the crane is lifted to the material rack, and the bar is pulled into the conveyor roller by the automatic material turning mechanism.

Heating: After setting the heating temperature of steel ball production line, it is automatically controlled by PLC.

Rolling: Main motor frequency conversion speed regulation, to meet the speed requirements of different specifications of steel balls, matching with medium frequency induction heat treatment equipment;

Conveyor hoist isotherm: conveyor hoist frequency conversion speed regulation, adjust the temperature of hot rolled steel ball production line.

Quenching; quenching inner spiral drum frequency conversion speed regulation, adjusting the temperature of steel ball after quenching;

Aggregate and cooling enter the off-line resistance furnace for tempering treatment (steel balls below 50mm can directly enter the residual temperature of the insulation box for self-tempering)

Cooling; cooling the steel ball to normal temperature;

Inspection packages are put into storage; after inspection, packages are put into storage according to packaging requirements.

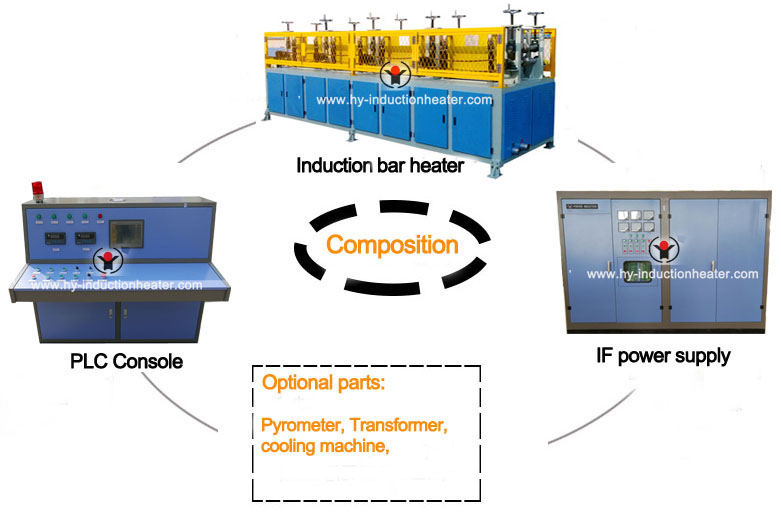

Composition and Application of Ball Heat Treatment Furnace:

Induction heating furnace and temperature control device are composed of induction heating power supply, furnace cabinet, capacitor bank, diathermic furnace body, pinch roller, power supply furnace body link line, operation console, infrared thermometer, PLC control system and so on. For round billet heating to rolling temperature into skew rolling mill rolling, heating furnace adopts advanced infrared temperature closed-loop control. The production efficiency and heating temperature of ball heating heat treatment equipment can be set by PLC parameters, which can completely match rolling speed of rolling mill to realize isothermal rolling in rolling process. Secondly, induction heating has no oxidation on billet surface compared with gas furnace and coal-fired furnace. Heating uniformity can be stopped immediately, occupying a small area can be connected to an automated production line, avoiding the waste of billet heating caused by subsequent mechanical failure.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.