Hardening And Tempering Furnace

Features:

Application: Hardening & Tempering

Material Heated:45#、40Cr、42CrMo、65Mn

Diameter Allow: Φ20-110mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Hardening And Tempering Furnace

Typical Application:

Forever hardening and tempering furnace has self-designed MF and HF power supply and mature induction heating technology. Forever will be responsible for fabrication supply & commissioning of hardening and tempering furnace for your work piece to meet your production requirements. For hardening and tempering furnace, Forever has already had many cases, so we are very familiar with the heat treatment process for different material of work piece.

Hardening and tempering furnace application

● Mining machinery: Single prop, long metal beam, U type steel frame, type beam, grinding rod, bulldozer blade

● Auto parts industry: Stabilizer, leaf spring, torsion bar

● Petroleum machinery industry: Drill pipe, drill collar, sucker rod, tubing, casing, seamless pipe, weld pipe

● Wind power industry: Wind turbine bolt, anchor bolt

Hardening processes are used to improve specific mechanical properties to a component in order to render it fit for use.

Tempering is a low temperature (150ºC to 650ºC) heat treatment intended to remove the stresses and brittleness caused by quenching and to develop the required mechanical properties.

Hardening and tempering furnace advantages

● Uniform heating, very less oxidation

● Frequency Control and heating times

● Cooling control

● Energy saving

● No physical contact

● Control and located heat

● Can be integrated in production lines

● Improved environmental conditions

● Good heat treatment effect, no need straightening

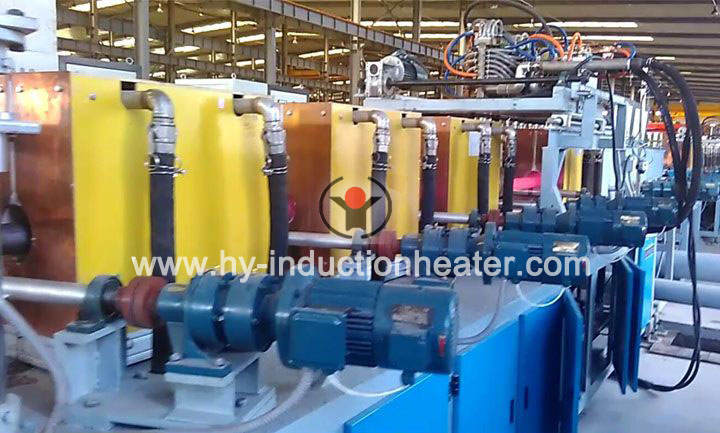

Hardening and tempering furnace parts

● Automatic feeder,transmission device

● Induction heating furnace

● Quenching box

● Tempering furnace

● Automatic discharging

● IF power supply

● Remote console

| Steel bar diameter | Automatic Control | Power Design |

| Ø10-Ø28 mm | IPC Control | KGPS350KW Quenching+KGPS160KW Tempering |

| Ø42-Ø48 mm(Anchor Bolt) | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-60 mm | IPC Control | IGBT250KW Quenching+IGBT160KW Tempering |

| Ø30-Ø60 mm | PLC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø35-Ø60 mm | IPC Control | KGPS250KW Quenching+KGPS160KW Tempering |

| Ø30-Ø110 mm | IPC Control | KGPS400KW Quenching+KGPS400KW Tempering |

| Ø80-v110 mm | PLC Control | KGPS600KW Quenching+KGPS160KW Tempering |

As our continuous quenching and tempering furnace is all customized, the above parameters are only for your reference.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment and system in China; Glad to be your business partner in induction heating field.