The Forever steel ball hot rolling production line is designed for efficient and high-precision production of bearing steel balls, wear-resistant steel balls, etc. It has the characteristics of high automation, energy conservation and environmental protection, and strong stability. The following are the installation requirements for its steel ball production line:

1. Basic conditions

Venue requirements:

Production line length: According to the capacity configuration (usually 50-120 meters), sufficient space needs to be reserved (including raw material area, rolling area, cooling area, and collection area).

Ground bearing capacity: ≥ 5 tons/m ² (due to the large weight of the equipment, concrete reinforcement is required for the foundation).

Factory height: ≥ 8 meters (ensuring space for crane lifting and equipment maintenance).

Power supply:

Voltage: 380V ± 10%, 50Hz (high-power steel ball production line requires high voltage 10kV connection).

Total power: 500~2000kW (depending on the specifications of the rolling mill, a voltage regulator device is required).

Gas source and cooling water:

Compressed air: 0.6~0.8MPa, flow rate ≥ 3m ³/min (used for pneumatic clamping and blowing).

Circulating cooling water: pressure 0.3~0.5MPa, water temperature ≤ 30 ℃ (to prevent equipment overheating).

2. Environmental requirements

Temperature: 5-40 ℃ (to avoid extreme temperature affecting the hydraulic system).

Humidity: ≤ 80% (to prevent electrical components from getting damp).

Dust control: Dust removal equipment (especially for rolling oxide skin treatment) is required.

3. Installation process

Foundation construction: Pre embed anchor bolts according to the drawings to ensure a horizontal error of ≤ 2mm/m.

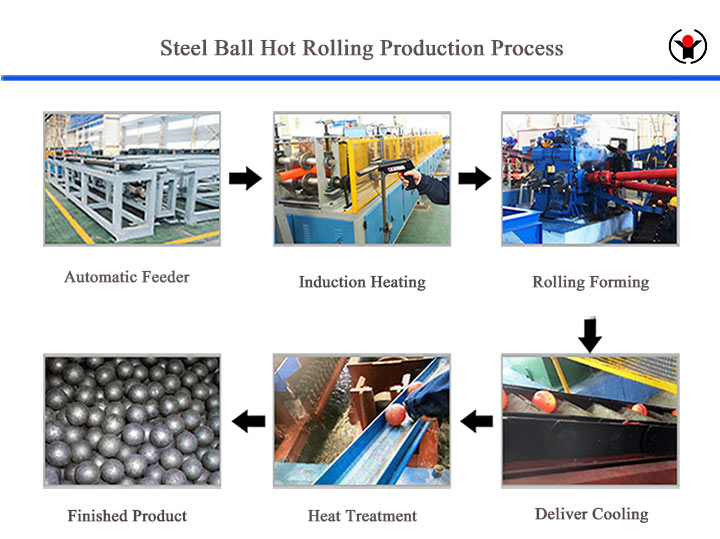

Equipment positioning: Use a crane/forklift to lift in sections and arrange them in the process sequence (heating furnace → rolling mill → quenching wire → collection platform).

Leveling calibration: Laser level is used to detect the parallelism of the rolling mill (error ≤ 0.05mm).

Electrical wiring: frequency converter PLC、 Sensors and other connections have a grounding resistance of ≤ 4 Ω.

Trial operation: No load test → Low speed running in → Load test (gradually increase to rated capacity).

When installing the steel ball skew rolling production line , it is necessary to strictly follow the basic installation requirements and pay attention to the debugging and optimization of the later automation system.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-10-2025