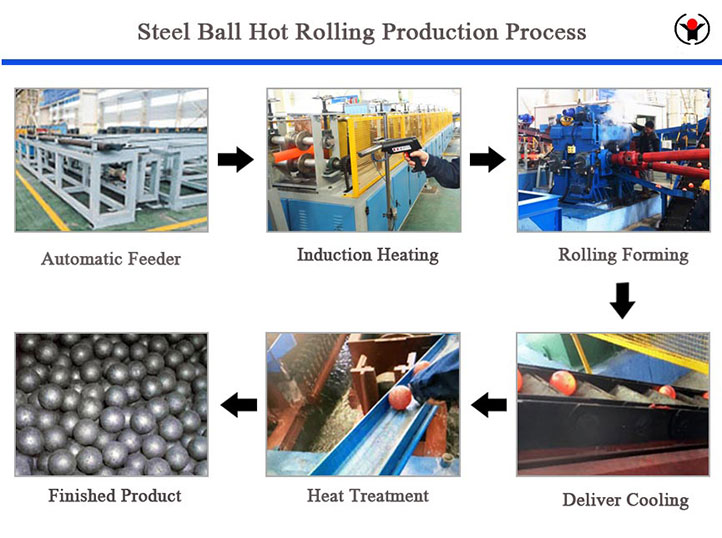

The Forever steel ball hot rolling production line is an efficient and high-precision steel ball manufacturing system that uses skew rolling or spiral rolling technology to directly roll heated bar materials into ball blanks. It is suitable for mass production of bearing steel balls, grinding medium balls, hardware accessories and other products.

Its core competitiveness is as follows:

1、 Efficient production, industry-leading production capacity

Continuous rolling:

The single steel ball production line production capacity can reach 2000~5000 pieces/minute (with a diameter of 10mm steel ball), which is more than 10 times faster than forging a single piece.

Support 24-hour uninterrupted production, suitable for large orders (such as bearing steel balls with an annual production capacity of over 10000 tons).

Quick mold change:

Replacing the rolling mill mold only takes 30 minutes, suitable for the production of multiple specifications of steel balls (Φ 5mm~Φ 150mm).

Compared to traditional craftsmanship:

Casting: Low efficiency (≤ 500 pieces/minute), requiring separate cleaning of burrs.

Cold heading: only suitable for small-sized balls (< Φ 20mm), with low material utilization rate.

2、 Ultra high material utilization rate, reducing costs

Near Net Shape:

After rolling, the ball billet approaches the final shape with a material utilization rate of over 90% (traditional turning processes only have 50% to 60%).

Waste recycling:

Scrap materials and defective products can be directly melted back into the furnace, with a comprehensive waste rate of less than 5%.

economic performance:

Each ton of steel balls can save 20% to 30% of raw material costs (taking GCr15 bearing steel as an example, saving millions of yuan annually).

3、 Key technical support:

Intelligent temperature control system: PID ± 5 ℃ precise temperature control to avoid overburning or uneven organization.

Online detection: laser caliper+AI visual sorting, real-time removal of non-conforming products.

4、 Energy saving and environmentally friendly, in line with the trend of green manufacturing

Induction heating technology:

Compared to gas stoves, it saves 30% energy and reduces carbon emissions by 40%.

Waste heat recovery:

Preheating new bar materials using quenching waste heat, with a comprehensive energy consumption of ≤ 0.8kWh/kg.

Zero wastewater discharge:

Adopting a closed-loop cooling system, the cooling medium is circulated for use.

Environmental certification:

Compliant with ISO 14001 and EU RoHS standards, helping customers pass ESG audits.

5、 High degree of automation and intelligence

Full process automation:

From bar feeding to rolling, heat treatment, sorting, and packaging, there is no human intervention throughout the entire process.

Digital twin monitoring:

Real time monitoring of device status through the Internet of Things (IoT), predicting maintenance needs (reducing downtime by 20%).

AI process optimization:

steel ball skew rolling production line learning algorithms automatically adjust rolling parameters (such as roll pressure and speed), improving the yield rate to over 99%.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-22-2025