long bar induction heat treatment & QT line

Features:

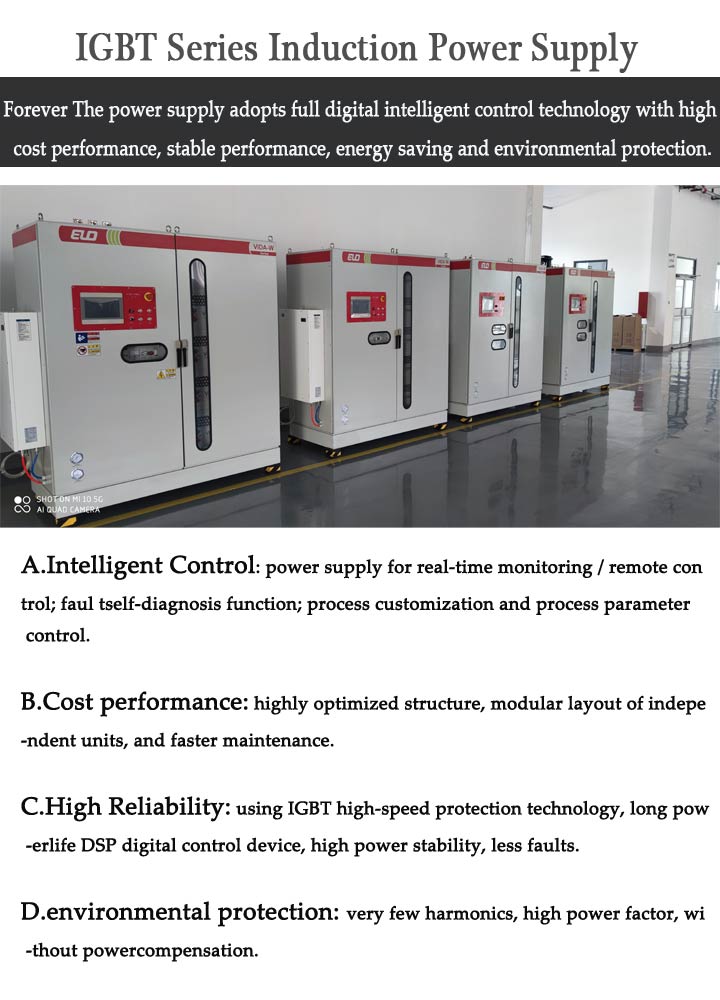

Model: IGBT

Brand: Yuantuo Electromechanical

Alias: Steel Bar Quenching and Tempering Furnace

Usage: Quenching and Tempering Heat Treatment

Product Detail

Application Video

Product Tags

The long bar induction heat treatment machine is an equipment used in the metal heat treatment industry for quenching and tempering of metal workpieces such as bars and steel bars. Based on your actual process needs, we match you with a cost-effective bar quenching and tempering production line. Currently, our Yuantuo Electromechanical Manufacturer can produce quenching and tempering heat treatment equipment for bar diameters of 10-150mm.

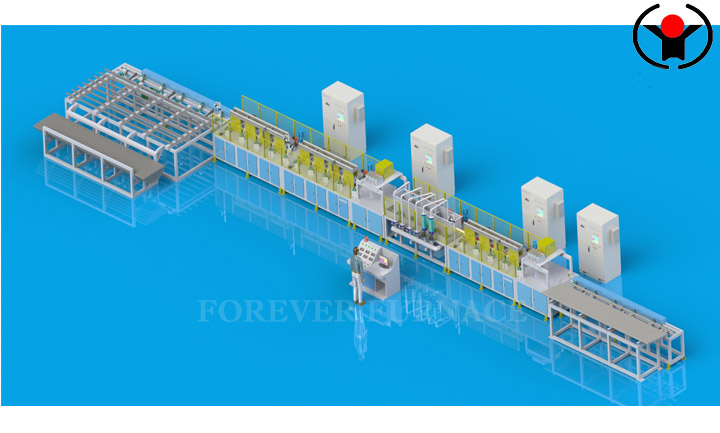

Conveyor roller conveyor: The axis of the roller conveyor forms an angle of 18-21 ° with the axis of the workpiece. The workpiece rotates while feeding at a constant speed, making heating more uniform. The roller conveyor between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled.

Roller grouping: The feeding group, sensor group, and discharge group are independently controlled, which is beneficial for continuous heating without creating gaps between workpieces.

The spray system adopts multi-stage spray cooling, and the pressure and flow rate between each level of spray can be adjusted to meet the requirements of different hardenability.

The complete set of long bar induction hardening and tempering machine consists of the following parts:It consists of intelligent intermediate frequency quenching, intermediate frequency tempering, closed water cooling system, storage rack, mechanical feeding device, infrared temperature measurement, spray cooling system and central control system.

The characteristics of long bar induction heat treatment furnace :

1. Sensor design:

Design different sensor groups based on different parameter workpieces, with a wideband design to achieve high heating efficiency for workpieces of a wide range of sizes. Increase the number of tempering sensors in each group and add insulation buckets to obtain a good tempering structure and ensure that the workpiece performance meets the requirements.

2. Roller conveyor in front of the furnace and between the furnace bodies:

Made of 304 non-magnetic stainless steel, tilted and water-cooled, greatly extending the service life of the channel,

3. Spray system:

The spray ring of the bar quenching and tempering production line adopts multi-stage stainless steel spray rings, and the pressure and flow rate of the spray rings are independently adjusted to meet the requirements of different hardenability.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.