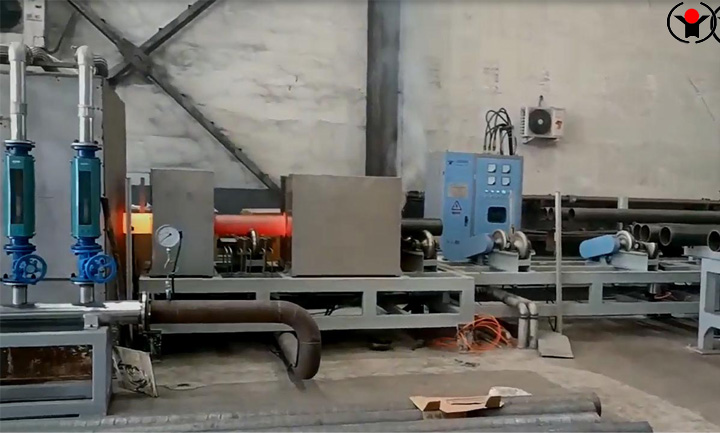

Induction heating technology is an efficient and precise heating method applied in the steel pipe processing industry. As an important tool in industrial production, steel pipe heating equipment has become an important choice for many enterprises to achieve process upgrades due to its efficiency and adaptability. Hebei Forever Electromechanical will systematically introduce the technical characteristics and usage scenarios of steel pipe induction heating furnace from three aspects: working principle, application advantages, and process adaptation.

The steel pipe heating equipment adopts the principle of electromagnetic induction heating, which generates an alternating magnetic field through high-frequency or medium frequency current and acts on the surface or interior of the steel pipe to achieve fast heating speed. This process mainly includes the following steps:

The main component of Steel pipe induction heating furnace is the induction coil, which generates an alternating magnetic field when powered on. When the steel pipe is placed inside the coil, the magnetic field passes through the surface of the steel pipe.

According to the law of electromagnetic induction, an alternating magnetic field excites eddy currents in steel pipes. These vortices generate heat when flowing inside the metal, causing the steel pipe to heat up quickly.

Induction heating has non-contact characteristics, which can ensure uniform heating of the steel pipe surface and reduce mechanical wear.

By adjusting the current frequency and power of the induction coil, as well as the heating time of the steel pipe, the steel pipe medium frequency heating equipment can achieve precise temperature control, meeting different process requirements such as annealing, quenching, tempering, and preheating before hot rolling.

Compared to traditional heating methods such as gas heating, induction heating equipment reduces intermediate energy loss and significantly improves energy utilization by directly acting on steel pipes.

Through modern control systems, steel pipe heating equipment can achieve fully automated operation, including temperature regulation, process management, and fault diagnosis.

Steel pipe heating equipment can adapt to steel pipes of different diameters, wall thicknesses, and materials, and is used in the petroleum pipeline, construction steel, and mechanical processing industries.

If you need further information on the specific configuration scheme or technical support of steel pipe heating equipment, please feel free to consult us. Hebei Forever Electromechanical Equipment Manufacturing Co., Ltd. will provide you with solutions to help you upgrade your production.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-18-2025