Composition of sucker rod induction heat treatment equipment :

power supply system

DSP fully digital control device, after process adjustment and load adjustment, can adapt to variable frequency and load, automatically adjust power and stabilize control.

roller conveyor

High precision design ensures zero material wear, and the conveyor roller of the material rack adopts a double roller design, which is smooth and wear-resistant, and will not damage the workpiece during use.

Industrial computer system

In order to effectively ensure the heat treatment effect of the workpiece, our Sucker rod induction heat treating furnace adopts a temperature closed-loop control system in both heating and quenching processes, with high temperature precision.

Features of Sucker rod hardening and tempering furnace :

The operation panel adopts a large-sized touch screen and high-definition operation screen, allowing even first-time users to operate with peace of mind;

The user-friendly design of a sound operating system greatly shortens the preparation work for using the device; Advanced automatic diagnostic system provides assistance for equipment troubleshooting and repair;

Adopting an intelligent PLC control system to ensure the stability of work;

The feeding system adopts 304 non-magnetic stainless steel, which is wear-resistant and has a long service life;

Fast heating speed, high production efficiency, and minimal oxidation and decarbonization.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

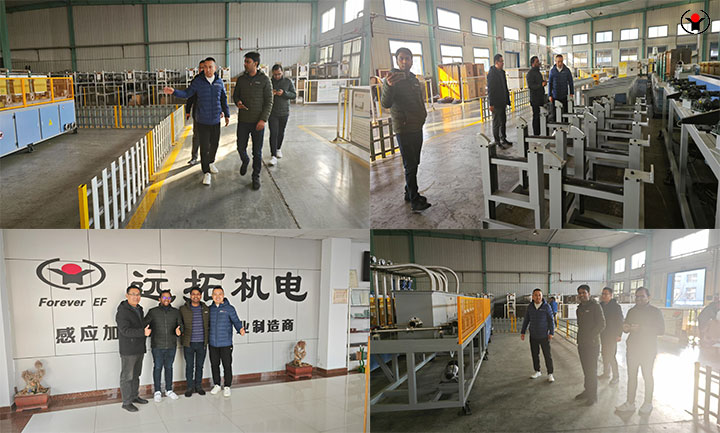

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-16-2025