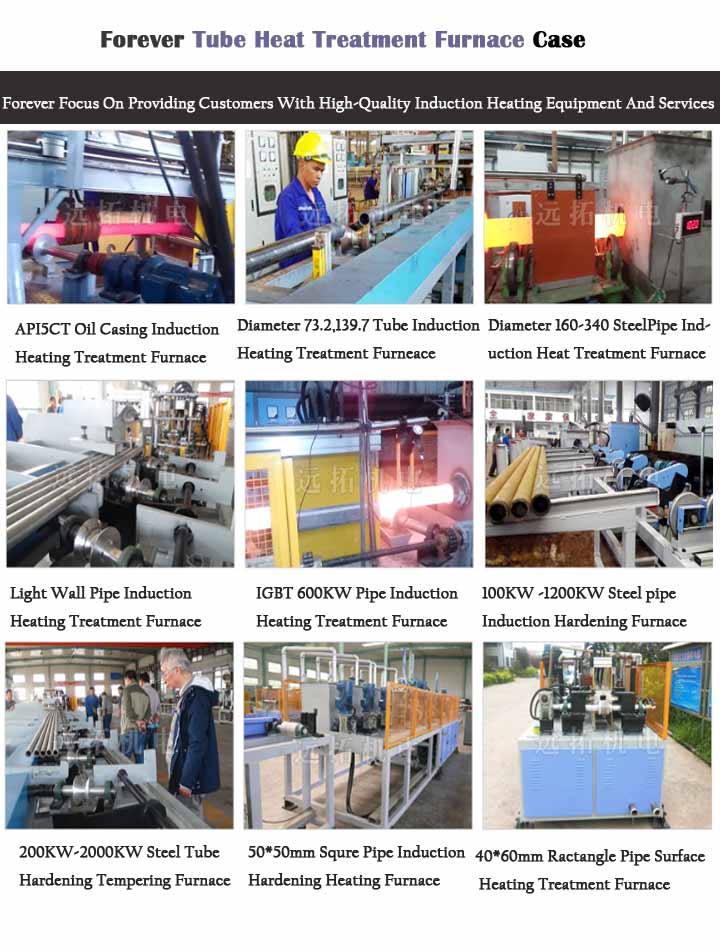

The hardening and tempering process (hardening+high-temperature tempering) in the Forever Steel pipe heat treatment equipment is the core link to improve the comprehensive mechanical properties (strength, toughness, fatigue resistance) of steel pipes, especially suitable for medium and high carbon steel and alloy steel pipes such as petroleum casing, mechanical structural pipes, and high-pressure boiler pipes

1、 Core process of hardening and tempering technology

1. Hardening stage

Heating equipment:

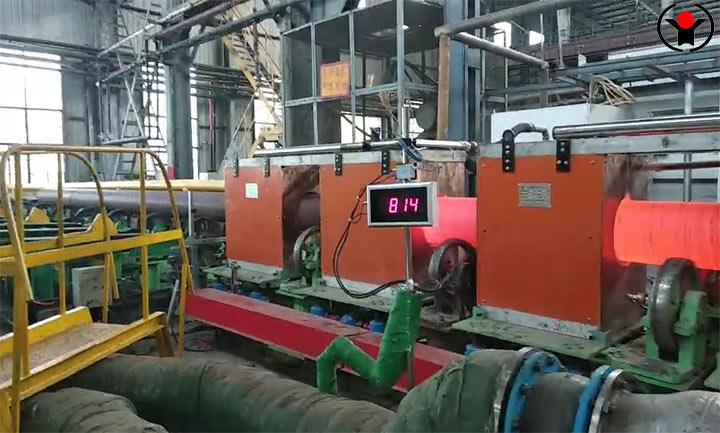

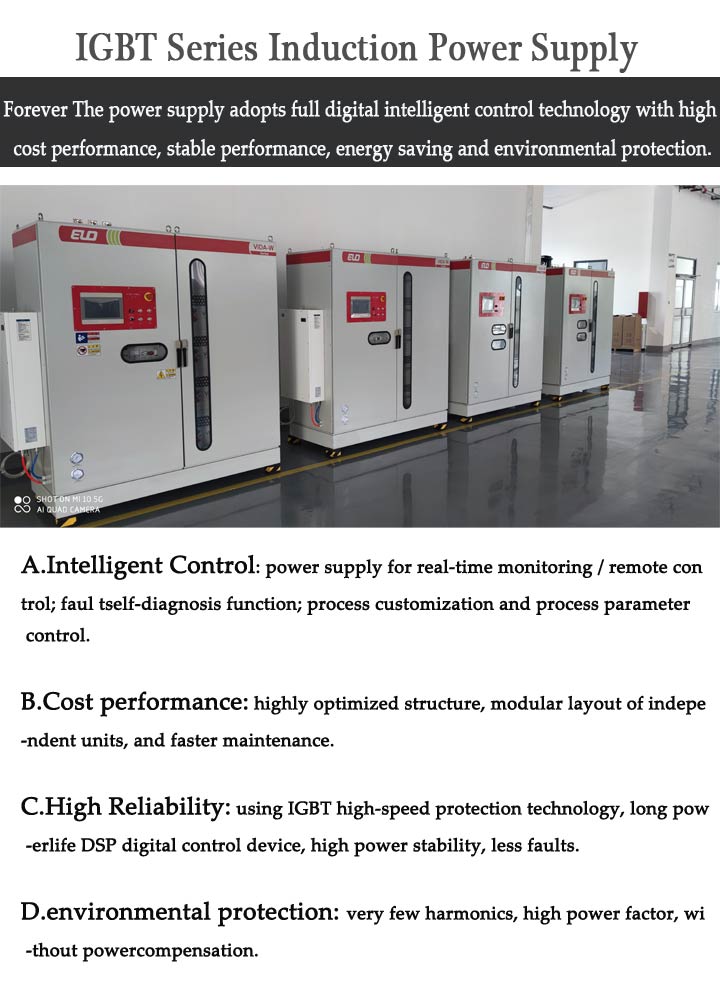

Induction heating furnace (Forever advantage equipment): Quickly heat to above Ac3 (such as 45 steel: 850~880 ℃), with controllable heating rate (100~200 ℃/s), to avoid grain coarsening.

Gas/electric heating furnace: suitable for large-diameter thick walled pipes (such as Φ>300mm), requiring protective atmosphere (nitrogen) to prevent oxidation.

Temperature control: Infrared thermometer+PLC closed-loop regulation, temperature difference within ± 5 ℃, ensuring uniform austenitization.

Cooling medium:

Water hardening: suitable for low-carbon alloy steel (such as 27MnCrV), with a fast cooling rate, but it needs to prevent deformation and cracking.

Polymer hardening solution (such as PAG): commonly used for medium and high carbon steel (such as 42CrMo), with adjustable cooling rate to reduce stress.

2. Tempering stage

Tempering temperature: High temperature tempering (500~650 ℃), adjusted according to the material and target hardness (e.g. 40Cr: hardness HRC 25~30 after tempering at 550 ℃).

steel pipe induction hardening and tempering line type:

Continuous tempering furnace: linked with hardening wire, high efficiency (standard configuration on Forever production line).

Trolley type resistance furnace: suitable for small batch customized production.

Key parameters:

Insulation time (wall thickness × 1.5~2 min/mm) to ensure sufficient precipitation of carbides.

2、 Advantages of hardening and tempering technology in Forever steel pipe heat treatment production line

1. Precise process control

Dynamic adjustment system: automatically matches heating power and cooling rate according to steel pipe specifications (diameter, wall thickness) (such as reducing water pressure and preventing deformation for thin-walled pipes).

Hardness prediction model: Based on material composition and process parameters (such as hardening cooling rate), predict the hardness after tempering to reduce trial and error costs.

2. Efficient and energy-saving design

Waste heat recovery: After hardening, the waste heat from high-temperature steel pipes is used for preheating the tempering furnace, reducing energy consumption by 15% to 20%.

Induction heating is energy-saving: more than 30% more energy-efficient than resistance furnaces, especially suitable for small and medium-sized steel pipes (Φ 20~200mm).

3. Quality consistency assurance

Online detection system: eddy current testing (surface cracks)+ultrasonic thickness measurement (wall thickness uniformity), real-time removal of non-conforming products.

Metallographic monitoring: Regular sampling and inspection of martensite/martensite transformation rate (as required by API 5L standard).

Forever provides customized equipment services that are compatible with various processes such as tempering, normalizing, and annealing. Support MES system integration to achieve process traceability and quality big data analysis.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-06-2025