Want to know more about long shaft quenching? Come here !

The technological process of the long shaft hardening heat treatment furnace: the long shaft is heated rapidly by induction steel bar quenching furnace and then moves in a uniform straight line. After heated to 1100 C ~ 1400 °C, the workpiece enters the quenching water tank in a straight line. The induction scanning and the high-grade sprinkler quenching are carried out at the same time. Inductor with water spray, so that the workpiece can be heated to the required temperature can immediately cooling with water spraying, this can ensure the depth of hardening layer and quenching hardness.

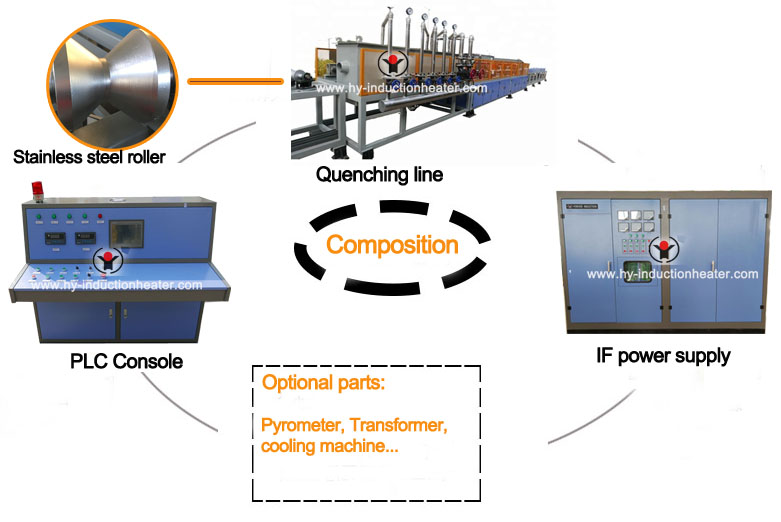

Shaft hardening heat treatment furnace is mainly suitable for the quenching heat treatment of various metal shafts such as shafts, step shafts, gear shafts, long shafts, outer circles of half shafts, end faces and so on. The machine has features of low running cost, high automation degree and can achieve process of high temperature heating, stranght roller conveying, spraying and air cooling. Siemens PLC control system can make the record for different production parameters such as temperature, speed, pressure, flow, temperature curve and so on.

IGBT of shaft hardening heat treatment furnace is a characteristic device. The circuit adopts series resonance circuit and the inductor is safe voltage. It has small volume, light weight, easy installation and operation, energy saving and power saving. Quenching temperature and heating time can be accurately controlled, high processing quality; fast heating speed, no oxide layer, deformation is small; energy saving, power saving 30% than old type furnace.The long shaft quenching inductor is isolated from the transformer to ensure the use safety. There is no noise and dust. It meets the requirements of environmental protection and pollution-free. It can be said that modern shaft hardening equipment is the ideal choice.

The water quenching and cooling system of the long shaft hardening heat treatment furnace is composed of a collecting pool, a water spraying induction coil and a pipeline. A plurality of sprinklers are arranged between the rollers. Each induction billet heater is connected with the main pipe through a valve and can adjust the flow rate of cooling water separately. The center of the sprinkler ring can be adjusted according to the change of the long axis. Shaft quenching sprinkler is a combination of material science and heat treatment profession, using stainless steel material made of circular sprinkler. It is installed in the discharge end of the inductor, the long shaft will go through the inductor. High-pressure cooling water from the sprinkler will quench the workpiece. The long shaft quenching spray device is equipped with a collecting tank and the cooling water flows into the quenching circulating pool through the sink.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 09-20-2018