Forever has experienced engineers who have worked in the field of induction heating for many years. They have rich experience and practice in the design, process, manufacturing, and management of sheet metal quenching and tempering furnaces. Forever focuses on providing customers with excellent sheet metal quenching and tempering heat treatment furnaces, professional formula management systems, high production efficiency, and free sheet metal quenching and tempering furnace solutions and quotations.

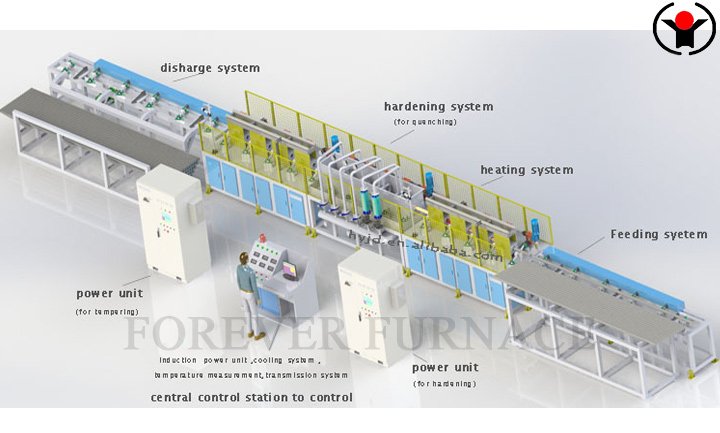

Introduction to the configuration and working performance of the mechanical part of the Steel plate induction heat treatment furnace :

1. Roller conveyor with dual pressure rollers, each axis driven by an independent motor reducer and controlled by an independent frequency converter, enables the steel plate to move forward flexibly and uniformly on the roller conveyor, ensuring uniform heating of the workpiece. The water-cooled roller variable frequency drive method is used for feeding, and the workpiece is transported at a constant speed. Induction devices are installed on the conveyor line to ensure smooth passage of the plate through the rollers.

2. The frame of the transmission mechanism has sufficient strength and rigidity. In order to facilitate equipment installation, adjustable feet are installed at the bottom of the frame to make the equipment more beautiful as a whole. According to the safety standardization requirements of the mechanical industry, all mechanical rotating exposed parts are installed with reliable protective devices, and the production line should comply with national environmental protection standards.

3. The Steel plate induction hardening and tempering furnace is energy-saving and efficient, with uniform heating. After quenching and tempering, the steel plate has no cracks or deformations.

Characteristics of steel plate quenching and tempering furnace:

1) Simple operation, flexible feeding and unloading, high degree of automation, capable of achieving online production;

2) Fast heating speed, minimal oxidation and decarburization, high efficiency, and good forging quality;

3) The heating length, speed, temperature, etc. of the workpiece can be accurately controlled;

4) Uniform heating of the workpiece, small temperature difference between the core and surface, and high control accuracy.

5) Meets environmental requirements, causes minimal pollution, and also reduces the labor intensity of workers.

6) The steel plate quenching and tempering furnace equipment adopts medium frequency induction heating power control, fully digital tuning, and can achieve high-power automatic adjustment.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 06-05-2025