long bar induction heat treatment machine play a crucial role in the metal processing industry, with their main functions including the following aspects:

Heat treatment: The main function of Induction heat treatment furnace is to perform heat treatment. Heat treatment is a process of changing the internal structure of metal materials through heating, insulation, and cooling to obtain the desired physical and chemical properties. By appropriate heating and insulation in a heating furnace, steel bars can reach the required phase transition temperature, causing changes in their microstructure and properties, such as increasing hardness, strength, toughness, or improving their processing performance.

Preparation processing: Prior to certain processing procedures such as forging, hot rolling, welding, etc., it is necessary to preheat the steel bars. The steel rod heating furnace can provide a stable and controllable heating environment, ensuring that the steel rod reaches an appropriate temperature before processing, reducing stress and deformation during the processing, and improving processing efficiency and product quality.

3. Stress removal: Steel bars may experience internal stress during the manufacturing process due to uneven cooling, mechanical processing, and other reasons. Proper heating and insulation through a heating furnace can promote the release and redistribution of stress inside the steel rod, thereby achieving the goal of stress removal and improving the stability and service life of the steel rod.

Softening treatment: For certain steel bars that require softening (such as steel that needs to improve cutting performance), the heating furnace can control the heating temperature and holding time to bring the steel bars to the softening temperature range, thereby achieving softening treatment.

Annealing treatment: Annealing is a heat treatment process that improves the microstructure and properties of steel by heating it to a certain temperature and holding it for a certain period of time before slowly cooling it. Steel bar heating furnace can be used for annealing treatment to induce phase transformation and recrystallization of steel bars during the annealing process, thereby obtaining the required mechanical and processing properties.

Heating straightening: For some steel bars that need to be straightened due to bending or deformation, a heating furnace can soften them and eliminate internal stress through heating, and then use straightening equipment to straighten the steel bars and restore their straightness and shape accuracy.

bar induction heat treatment furnace plays various important roles in the metal processing industry. It can not only improve the microstructure and properties of steel, but also enhance processing efficiency and product quality. It is an indispensable equipment in the metal processing process.

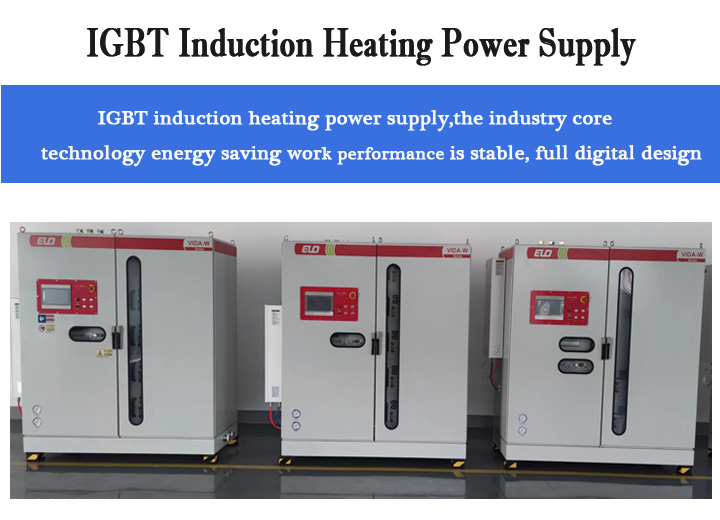

This is our IGBT induction heating power supply

Post time: 09-14-2024