Induction forging heating furnace

Features:

| Application | Steel strip / bar / billet / wire heating for forging |

| Power | 100 KW-8000 KW |

| Non standard | Professional customization |

| Temp.control | Infrared thermometer |

Product Detail

Application Video

Product Tags

Product Name: Induction forging heating furnace

Typical application:

Forever is providing induction forging furnace used for steel bar, steel billet, steel slab, steel strip heating before hot forging, hot rolling and warm-forming, improving production efficiency and reducing labor cost.

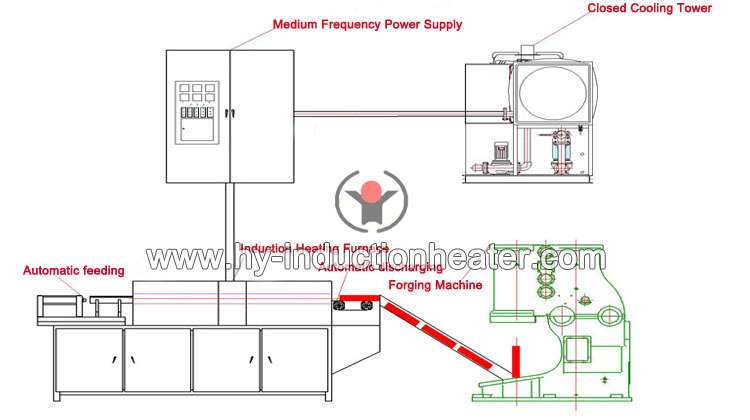

Automatic induction forging system drawing:

Induction forging furnace consisting of:

● Power supply: Full touch screen control, pure digital setting, with complete process record and strict purview control.The main parameters can be one key recovery of the factory settings.

● .Transmission roller table: The angle between roller axis and work piece axis is 18 ~ 21 °. The work piece is rotating and go forward at the uniform rate for uniform heating. Rollers between furnace are 304 non-magnetic stainless steel and water-cooled.

● For different sizes of work piece,the user can replace the corresponding inductors( the inductors are quick change structure, user can finish replacement within 15 minutes).

● Infrared temperature measurement : Setting infrared temperature measurement device at the discharge, so that the steel bar temperature can be controlled in the allowed range before charging into the rolling machine.

● Energy transformation : The power consumption is 280-310 KW/H for heating steel to 1000℃.

More information or videos about Induction forging heating system, please send email to Forever-induction heat treating equipment specialist.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.