Copper bar forging heating furnace

Features:

Application: Forging & Forging

Material Heated:Copper & Alloy Copper

Diameter Allow: Φ20-300mm

Length Allow:Not limited

Product Detail

Application Video

Product Tags

Product Name: Copper bar forging heating furnace

Typical Application:

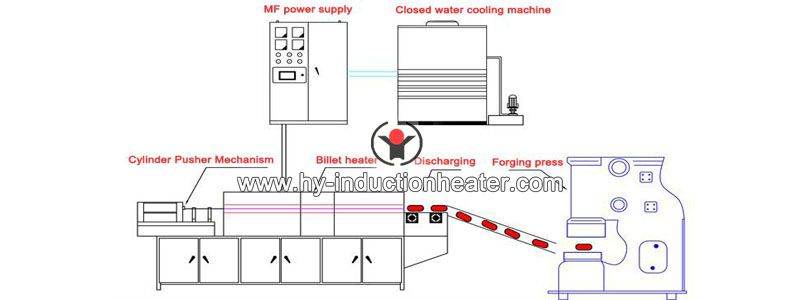

Copper bar induction heating forging machine is mainly used for the heating treatment for copper,copper alloy & aluminum before forging, extrusion and bending.

Forever copper forging heating machine is using induction heating technology, which is an accurate, fast, repeatable, efficient, non-contact technique for heating metals or any other electrically-conductive materials.

An induction heating equipment set consists of an induction power supply for converting line power to an alternating current and delivering it to a workhead, and a work coil for generating an electromagnetic field within the coil. The work piece is positioned in the coil such that this field induces a current in the work piece, which in turn produces heat.

The water-cooled coil is positioned around or bordering the work piece. It does not contact the work piece, and the heat is only produced by the induced current transmitted through the work piece. The material used to make the work piece can be a metal such as copper, aluminum, steel, or brass. It can also be a semiconductor such as graphite, carbon or silicon carbide.

Advantages

- Efficient and quick heating

- Accurate, repeatable heating

- Safe heating as there is no flame

- Prolonged life of fixturing due to accurate heating

Why should we choose Forever copper forging furnace?

1.Forever has nearly 20 years of induction heating and heat treatment experience and designed more than 1000 sets of inductors.

2.The parts of the copper forging furnace are selected from home and abroad famous manufacturers, such as programmable controller, close switch, infrared temperature measurement and display, frequency converter, low voltage control cabinet, etc.

3.Forever has its own technology research and development base and production base, and has successfully developed a high-power intelligent induction heating power supply.

4.Forever after-sale system is perfect, customer service response within 1 hours, one year warranty, life-long technology warranty.

As our billet induction heater is all customized, the above parameters are only for your reference.

Welcome to contact us at tom@foreverfurnace.com for more detailed price & solution.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.