Casing quenching tempering production line

Features:

Application: Quenching & Tempering

Material Heated:45#,40Cr,42CrMo,65Mn

Diameter range: not limited

Heating way: Induction heating

Product Detail

Application Video

Product Tags

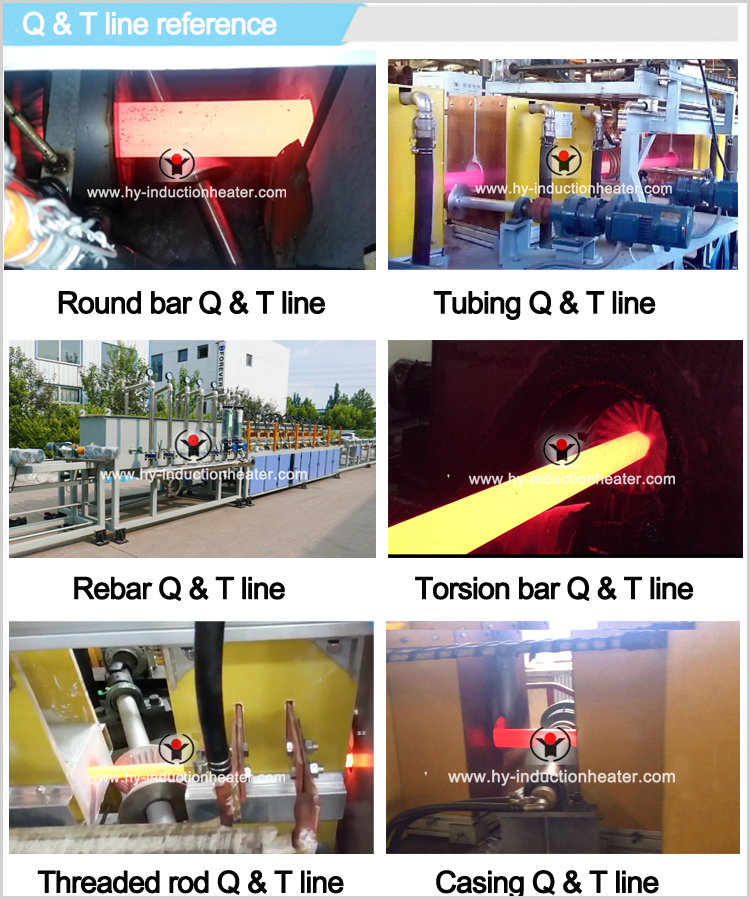

Casing quenching tempering line

● Product name:Casing quenching tempering line, Casing quenching and tempering production line

● Diameter range: not limited

● Length range: Not limited

● Product strength: Uniform heating, uniform quenching, good heat treatment effect

● Industry: Oil industry

Over two years development together with oil casing & tubing plant, Forever casing quenching tempering process has been mature. The practice proves that this process can make the casing quenching tempering line run in stable condition.

Main configuration for Casing quenching and tempering production line

● Energy saving IF power supply

● Storage platform

● Transportation roller system

● Induction heater for quenching

● Spray cooling system

● Induction heater for tempering

● Cooling platform

● Closed cooling machine

Master control part(Used for quenching & tempering)

● Customized human-machine interface,high user-friendly operation instruction.

● All-digital, high depth adjustable parameters that make you easy to control the equipment with great efficiency.

● Strict purview management system and perfect one key to restore system.

● Provide corresponding language switching according to different countries and regions.

The mechanical device

The mechanical device in this line includes pipe storage table, reverse pipe machine, transport roller, quick discharging machine, unloading machinery and sprayer.

● Pipe storage table and reverse pipe machine: the casing quantity on the storage table can be designed as per customer’s requirement. Reverse pipe machine is driven by cylinder, the casing will be turned down to the transport rollers.

● Roller table for transportation: it is installed in the inlet end of the inductor. Driven by a variable speed motor,its speed is slightly faster than heating roller. The speed is continuously variable adjustable.

● Transport rollers for heating: it is specially used for adjusting casing running speed during heating process. Driven by a variable speed motor, this transport rolls speed is adjustable according to the requirements of the heating process of different specifications of the products. As “V” type roller is working in the high temperature area, we punched in the center of the roll shaft and supply water to cool rollers.

● Transport rollers for discharging quickly: the roller is installed on the discharge end, driven by another speed motor. The rollers running speed is much faster than transport rollers for heating. After quenching for casing, roller motor will drive the casing out of quenching zone immediately.

● Unloading device: when the casing is transported to the roller table end, the sensor installed in the roller table end will issue an order of “Discharging”, then the cylinder below the roller will push the casing out of roller table. The casing will be rolled to storage area.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of billet induction heater in China; Glad to be your business partner in induction heating field.