Why should we do annealing for the steel pipe annealing? What is the significance of Steel pipe annealing furnace?

Why do we need to anneal the workpiece? What is the significance of this? Today, let’s talk about a Steel pipe annealing furnace. Firstly, what is steel pipe annealing? Pipe annealing is the process of heating the pipe to a certain temperature and holding it for a period of time, and then slowly cooling it. This process is called annealing.

Why do we need to anneal the steel pipe? What does this mean?

Because annealing the steel pipe through the steel pipe annealing furnace can eliminate the structural defects, improve the microstructure, homogenize the composition and refine the grain, improve the mechanical properties of the steel, reduce the residual stress; At the same time, it can reduce the hardness, improve the plasticity and toughness, improve the cutting performance. So annealing is not only to eliminate and improve the structural defects and internal stress left by the previous process, but also to prepare for the follow-up process, so the steel pipe annealing process should be carried out to reach the desired effect.

Steel pipe annealing furnace is of great significance to our development. Advanced pipe induction heat treatment furnace proves that heat treatment process is further on the road of advanced technology. High-end brand, high-end positioning, high-end quality, customized design and production, but also to meet the needs of different personalized users.

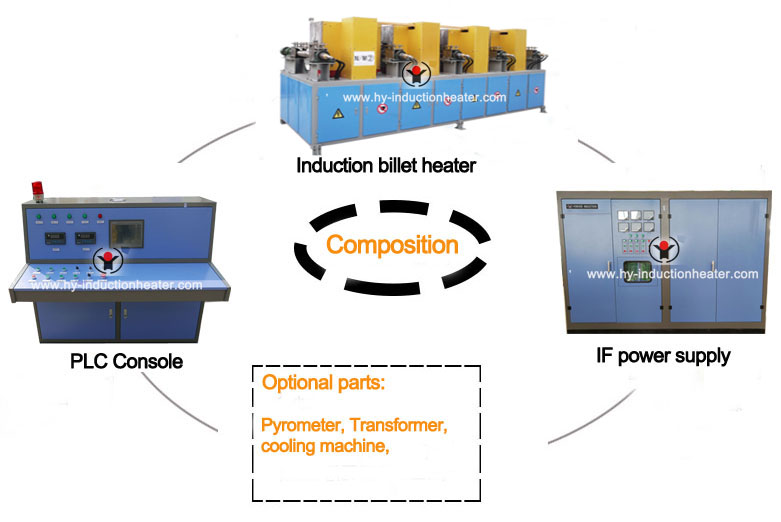

Forever steel pipe annealing furnace has a wide range of applications, including non-ferrous metal industry, copper industry and other bright heat treatment. The key parts of the equipment adopt international famous brands to ensure the service life. Traditionally, idler type synchronous transmission is adopted, frequency conversion speed regulation is stable and reliable. The supporting bearing is a special high temperature resistant bearing, conveying smoothly and ensuring the service life. The temperature and atmosphere distribute evenly in the furnace, thus ensuring the quality of high quality products. The unique cooling system of Forever enhances the cooling effect of the workpiece and ensures the cooling of the steel pipe within the prescribed time. The whole production line has complete and reliable automatic control of electrical appliances, safety interlock and alarm functions, and the operation is more safe. The controller is fully automatic intelligent controlled by PLC. With the computer, the production line can be monitored remotely. The pipe induction heating equipment of Forever has the advantages of high automation, no environmental pollution, smooth surface, uniform hardness and no oxidation.

Through the steel pipe annealing furnace, we can very well change the physical properties of its workpiece changes, get the standard we want, practical application to a variety of equipment and instruments, so that it can be better played to ensure its service life. Therefore, the induction heat treatment machine plays an important role in the development of heat treatment and its significance.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-04-2018