What furnace is used for tubing heat treatment? The device to help you solve the problem is coming!

Tubing is widely used for oil industry, which need high performance requirement through quenching heat treatment. Then, what equipment is used for tubing quenching heat treatment ? This article gives a brief introduction to this question.

With the development of science and technology, the design of high-efficiency tubing induction heat treatment furnace has become very mature, and the equipment configuration is more abundant. Tubing induction heat treatment furnace is usually recommended to meet customer requirements.

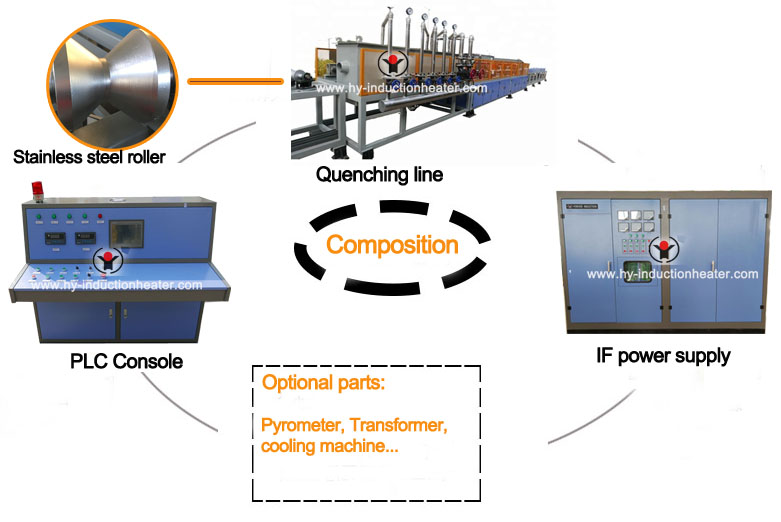

Tubing induction heat treatment furnace detailed configuration to meet your production needs.

Tubing induction hardening and tempering equipment mainly includes feeding mechanism, conveyor roller, induction heating system, water quenching cooling system, water circulation system, PLC remote control system and the corresponding motor, cabinet, etc. It is easy to use, energy saving. In addition, the equipment also has unique advantages:

1. The copper tube of pipe heat treatment furnace is winded by T2 oxygen-free copper, the wall thickness of the copper tube is more than or equal to 3.0 mm, the insulation material of quenching induction heating furnace is high in strength, high in temperature resistance and longer in service life.

2. Intelligent induction heating power supply adopts parallel resonance design, phase-shifting power regulation, mature and stable equipment; has more advantages over 3000KW in high-power range; cabinet adopts T2 copper bar, sandblasting and passivation treatment; low leakage inductance, oxidation resistance, effectively reduce line loss.

3. Automatic electronic control system, remote operation more convenient, customized man-machine interface, highly humanized operation instructions for the tubing heat treatment line; full digital, high-depth adjustable parameters, so that you can control tubing induction heat treatment furnace very easy; strict hierarchical management system, one key recovery system; the system can set language as per user’s local situation.

4. Powerful formula management system. After inputting the parameters such as steel grade and wall thickness to be produced, automatically recall the relevant parameters, no longer need to manually record, consult, input the parameters required by various workpieces.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-20-2018