Want to do heat treatment in your own plant? Come here !

Recently Forever received a few inquiries about solid bars continuous hardening and tempering furnace as they found that the heat treatment cost is increasing with their output capacity. It’s true that some plants will send their semi-finished steel products to the local heat treatment plant to do hardening and tempering. But later, with their scale expanding, they wish to have their own continuous hardening and tempering furnace in their plant to reduce their heat treatment cost.

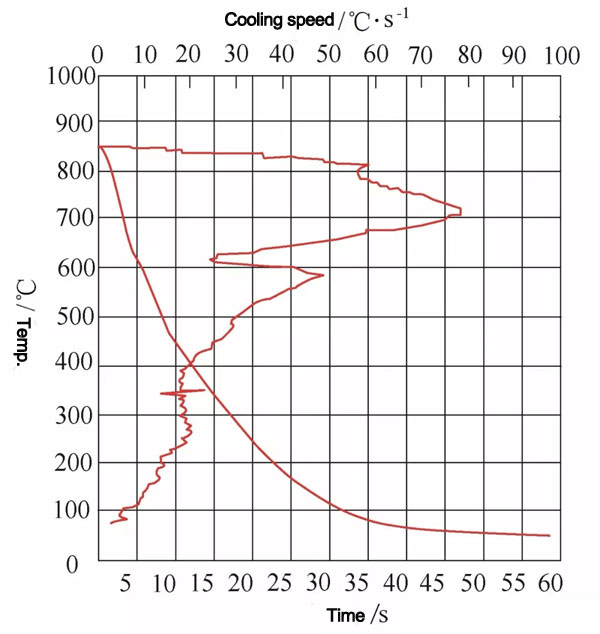

We can understand our customer’s mood, it will not only reduce a lot processing cost for their long bar induction heat treatment machine but also improving the product quality through studying the performance of finished products. It’s really a good idea to buy a set of bar continuous hardening and tempering furnace for their production. But a problem will puzzle customers’s mind, then what is it–it is the heat treatment process, which is very important to ensure the quality of the finished bars. Why did we say so ? As we all know, the purpose of hardening and tempering is to change the material internal microstruture and make the crystal become fine and uniform. Through changing the microstucture from ferrite to austenite and martensite-sorbide, the material hardness, tensile strength, yield strength and toughness will be greatly improved. Then which factor will effect the microstructure transform? The answer is the uniform heating temperature and uniform cooling for the material. If the bars can not obtain uniform heating temperature, the structure grain will not be homogeneous. It is the same with the cooling process. If the material surface can not get uniform cooling pressure and flow, then the austenite grain will be bigger or smaller, the structure performance will not stable, even the bar will bend or crack. Once there is crack on the bar surface, then this heat treatment process will be a failure. Of course, the bar straightness should be good before doing hardening and tempering.

But for the un-experienced customers, they don’t know the heat treatment receipe for hardening and tempering if they want to get some grade properties. If you come Forever, then you do not need to have worries about it. We have professional engineers who are involved in various heat treatment process for more than ten years and have got successful case from much practical machine operations. No matter what material or application is your workpiece such as grinding rod, torsion bar, turbine bolt, screw rod etc., we can all give you the right solutions to solve your heat treatment problem. After the long bar heat treatment machine arrived in your plant, we will send experienced engineer to guide you for installation, commissioning and simple training. Even you don’t have much knowledge for the hardening and tempering process, you only need to start the system, which will be running as per setting value.

After talking so much, you can realize that our machine is not only suitable for the experienced heat treatment plant but also can help an un-experienced user to do qualified products. So just tell us your workpiece material and the grade you need to get, then we will help you to build your own heat treatment line !

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 09-13-2018