There is a successful long bar heat treatment machine in the cold industry.

Long bar heat treatment machine is a brand new steel quenching equipment, servo motor drive with fast heating speed and high heating efficiency induction heating furnace; high-tech, environmental protection, low carbon; automatic operation and simple maintenace makes the quenching heat treatment working so easy !

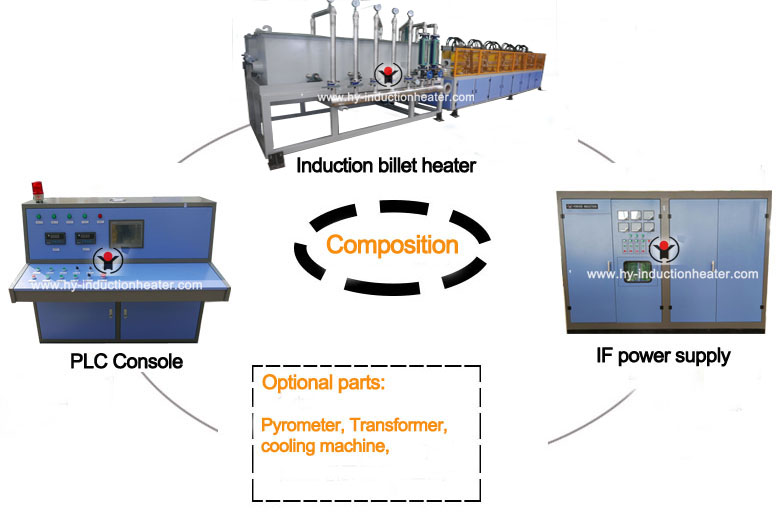

Servo motor drive, two-color infrared temperature measurement and display, PLC touch screen remote control console, a variety of equipment configuration matching. The long bar heat treatment machine consists of induction heating furnace, closed cooling system, storage table, quenching tank,feeding device, pyrometer device, discharging device and remote console. After input all the production parameters to the programme, then the system will run as setting technical parameters. The system can store more than 1000 recipes and user can call the previous production data at any time, which bring the great convenience for the unskilled operators.

High intensity structure reveals true skills.

Long steel bar quenching furnace is different from the general steel quenching furnace, its use of fully rigid structure chassis design, load bearing stronger, durability improve, greatly shortened the length of conveying. At the same time, it has many advantages to show the true ability of equipment.

1. Servo motor drive, energy saving and stability.

Chain cooling bed is welded by section steel and steel plate, driven by servo motor, multi-group sprocket and chain synchronous transmission; operation control is more intelligent, reduce energy consumption, stable operation, configuration of the corresponding load-sensitive control system, security has been greatly improved.

2. Strong driving force and capacity improvement.

According to different parameters of the workpiece, the computer is used to optimize the design of different inductor groups to meet the wide range of workpiece size to get higher heating efficiency. The induction furnace increases the number of each group and adds heat preservation barrel to get a good tempering structure to ensure that the workpiece performance meets the requirements. Strong power, save power consumption, increase production capacity, heating operation is more flexible, available to a variety of adverse working conditions.

Traditionally, the performance of the imported equipment is always considered superior than that of the domestic long bar induction heating equipment, but with the continuous innovation of science and technology, the production technology of the domestic equipment has been quite mature, and its function is no less than that of the imported products. At the same time, the imported equipment also has a natural advantage, that is more competitive prices.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-12-2018