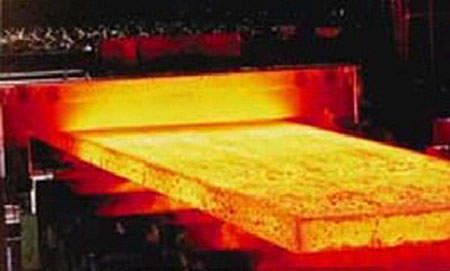

The forging and heating furnace of FOREVER mechanical and electrical plate materials adopts high-efficiency combined resonance technology, low inductance circuit arrangement, large-scale digital circuit, and comprehensive and mature protection technology. The plate material forging furnace is mainly used for the heating of metal materials before forging, extrusion, hot rolling and shearing, as well as the overall quenching and tempering, annealing, tempering and other heat treatment of metal materials. Yuantuo Electromechanical is a high-tech enterprise specializing in the development and production of induction heating equipment. Welcome to call for consultation. We will provide you with constructive technical solutions for continuous heating equipment for plates.

Outstanding advantages of plate forging furnace:

1. Medium frequency voltage double voltage output, wide output slot and small gap design of copper bar, reduce line power loss, and save power up to 10% – 15%

2. The furnace body of plate material forging heating furnace adopts double insulation treatment, which improves the service life and reliability by three times. The thin furnace lining design reduces space magnetic leakage, and the electric energy conversion efficiency is extremely high, achieving the purpose of energy saving and consumption reduction

3. Assembled induction furnace with convenient disassembly and assembly, new energy-saving furnace lining with long service life in China, and water cooling is not used for connecting copper bars in the daytime.

4. With high efficiency and energy saving, low burning loss of billets, it can meet the requirements of precision forming of most billets without adding protective atmosphere, and has the function of stopping heat preservation.

5. The automatic forging production line is composed of a full-automatic feeding machine, a discharging device, a blank temperature high and low sorting and a forging manipulator.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of bar heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 02-04-2023