Recently, the company has produced 3 sets of Turkey Long Bar Heat Treatment Machine with a range of 8-80mm in diameter

Suitable for tempering heat treatment of steel bars, carbon alloy steel, wind power bolts, screws and hydraulic cylinder rods.

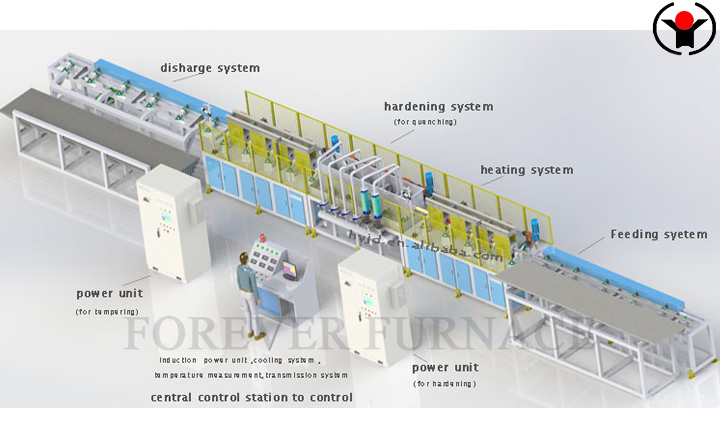

Composition of steel bar tempering furnace:

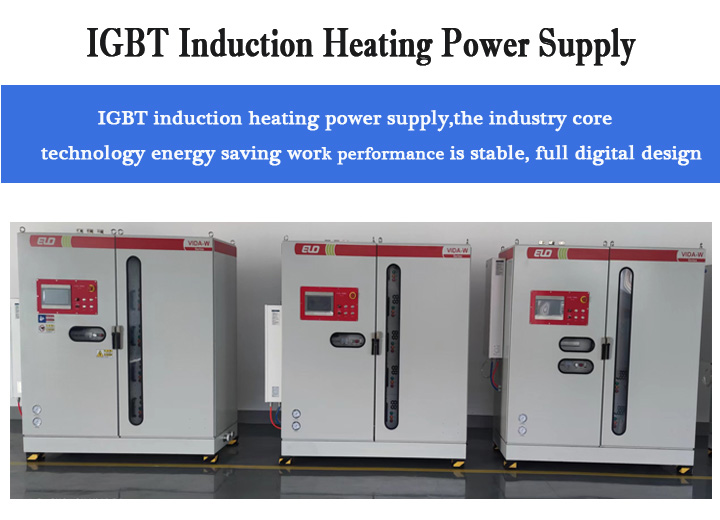

The Long Bar Heat Treatment Production Line comprises several key components: the input and output system, feeding structure, quenching induction heating system, quenching spray system, tempering insulation system, discharging system, and the PLC main control panel. Based on customer needs, optional equipment includes an infrared temperature measuring device, power transformer, low-voltage distribution cabinet, and closed cooling tower. If customers purchase these items independently, the supplier will provide relevant parameters. The medium frequency resonant medium frequency induction heating power supply for the steel bar tempering furnace can be selected based on actual conditions. It features full touch screen operation, fully digital setting, comprehensive process records, and strict level permissions. Additionally, the steel bar tempering furnace is equipped with a one-button reset function.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction billet heater in China; Glad to be your business partner in induction heating field.

Post time: 06-06-2025