If you want to make money by building steel mill, you only need such a set of long bar heat treatment machine.

“We want to build an iron and steel processing plant, the main processing materials are carbon steel, such as quenching and tempering process, is there any proper machines for us ? What is the estimated cost the whole line and how much hourly capacity can you machine achieve?” This is an active topic in the iron and steel processing industry in the recent user circle of friends. About the long bar heat treatment machine information, Forever will introduce for you.

Introduction to long steel bar quenching furnace.

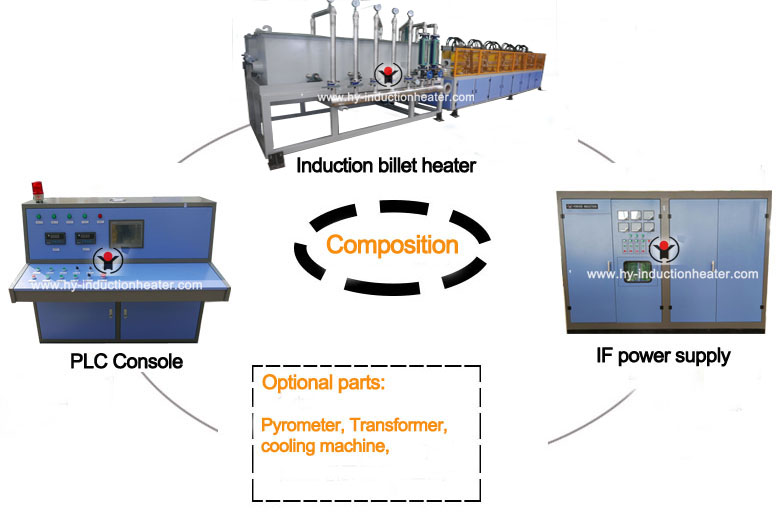

What equipment does the long bar heat treatment machine have? There are a lot of quenching machines in the industry. The structure, function and advantages of various quenching machines are not the same. It is really hard to choose for the users without experience. The following is a brief introduction to the induction quenching furnace of Forever company.

1. Induction Heating Furnace: Simple structure, high output, according to different parameters of the workpiece, using computer to optimize the design of different groups of inductors to meet the wide range of size workpiece to get higher heating efficiency.

2. Feeding and conveying roller: It is installed at the feeding end of induction heating furnace. It is powered by a variable-frequency speed regulating motor. Its running speed can be adjusted endlessly. Its running speed is slightly faster than that of heating and conveying roller.

3. Quenching water tank: Quenching sprinkler is a circular sprinkler made of 304 non-magnetic stainless steel. It is installed at the discharge end of the inductor. The steel bars pass through the sprinkler and the high-pressure cooling water sprays out from the sprinkler hole on the workpiece. There is a sink at the bottom of the sprinkler, and the cooling water flows into the quenching circulating tank.

4. Closed cooling tower: the soft water from induction heating equipment flows directly into the inlet of cooling tower, the soft water closed circulation does not contact with air, avoids scaling and clogging phenomenon and electrolysis phenomenon due to water quality problems, the cooling effect is good; no digging pool; easy to move and save space.

5. Discharging device: When the steel bar leaves the quenching water tank working area and reaches the end of the roller table, the sensor installed at the end of the roller table will issue a “discharging” instruction, so the cylinder under the roller table will push the the bars into the roller table and rolled into the platform table.

6. PLC general control part: specially customized human-machine interface, highly humane operation instructions. Full digital and high depth adjustable parameters make your control of long bar heat treatment furnace handy. According to different countries and regions, we will provide corresponding language switching.

Forever provides a full set of long bar heat treatment machine for users, welcome to visit our factory at Hebei province, China.

Contact person: Hailee Ma

Email:sales@foreverfurnace.com

Phone: 0086-18932783253(whatsapp, wechat)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 10-12-2018