How about the steel bar quenching furnace process?

Quenching heat treatment process is a heat treatment process to change the internal structure, properties and stress state of metal materials by induction heating furnace and cooling method. It is a key link to improve the performance, service life and reliability of products in the steel bar quenching furnace manufacturing industry. Mainly for metals, metal heat treatment is to heat metal or alloy materials to a certain temperature, holding a certain time in solid state, and then cooling at a certain cooling rate, that is, through the heating rate, holding time, holding temperature and cooling rate of the basic links of organic coordination, so that the metal or alloy materials internal group. The transformation of the fabric structure results in the improvement of the material properties. Forever steel bar quenching furnace related personnel said that quenching process mainly includes: heating, quenching, cooling and other steps. At the same time, the relevant personnel give a brief introduction about the operation of quenching operation.

Quenching operation: for example, the long bar is heated to a phase change temperature of Ac3 or Ac1, holding for a period of time and then cooled rapidly in other media such as water or air.

Purpose: The main purpose of steel bar quenching furnace is to obtain high hardness martensite structure. Sometimes when quenching some high alloy steel (such as stainless steel, wear-resistant steel), it is to obtain a single uniform austenite structure to improve wear resistance and corrosion resistance.

The main characteristics of long bar induction heat treatment machine

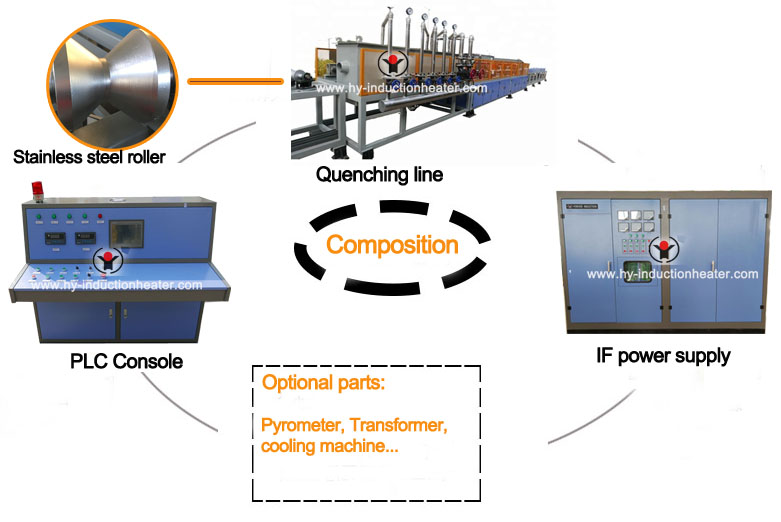

1. The induction heating equipment adopts PLC digital control system. It has advanced performance, convenient use, accurate positioning, and has the functions of connection, simultaneous, sectional connection and sectional simultaneous quenching.

2. High degree of automation, according to the workpiece process planning, automatic completion of heating, transmission, water spraying, rapid return.

3. The quenching method is diversified, which can be continuously scanned and quenched, so that the whole shaft quenched layer is uniform and the hardness is uniform.

4. The long bar induction heat treatment machine can be used for induction quenching of metal workpieces such as shafts, rods, tubes, aluminum alloys, etc. It has high precision and long service life.

5. The frequency of heat treatment quenching equipment can be according to the requirements of the workpiece processed by the user. The suitable hardening layer is 2-12mm. The hardness meets the requirements. There is no deformation, cracking, notch and oxidation decarbonization. The speed is 1/3 faster than that of SCR medium frequency.

6. Induction heating furnace inductor is open-close inductor, hardening without removing the workpiece, inductor can directly fasten the workpiece outer circle.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heating equipment is glad to be your partner in the field of induction heating.

Post time: 09-11-2018