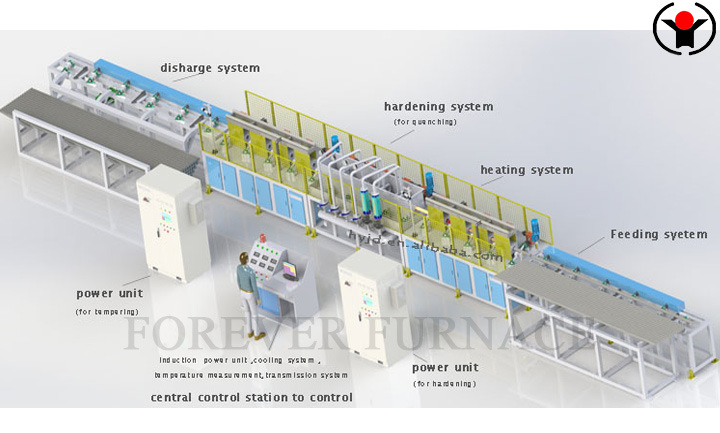

Forever steel plate induction hardening furnace adopts intermediate frequency induction heating technology. The principle is to generate an alternating magnetic field through an induction coil. When the steel plate is placed in this magnetic field, eddy currents will be generated inside the steel plate. Due to the resistance of the steel plate, the eddy currents will quickly heat the steel plate, thereby achieving rapid heating. During the quenching process, the steel plate is heated to the austenitizing temperature and rapidly cooled to room temperature. By adjusting the cooling medium (such as water, oil, or air cooling), the required hardness and strength are ensured on the surface of the steel plate.

advantage

Efficient and energy-saving: With fast heating speed, the steel plate can be heated to the desired temperature in a short period of time, saving time and energy. For example, compared with traditional resistance furnaces, its heating efficiency can be increased by 2-3 times, and the power consumption per ton after quenching is less than or equal to 500 degrees, which is much lower than resistance heating.

Uniform temperature: The induction heating temperature is uniform, with a small temperature difference between the core and the surface. The application of a temperature control system can achieve precise control of the heating temperature, improving product quality and quantity. At the same time, the plate induction hardening machine is equipped with multi-point temperature sensors to monitor the temperature inside the furnace in real time, ensuring uniform temperature during the heating process, avoiding local overheating or uneven cooling, and avoiding quality problems caused by temperature differences.

Environmentally friendly and pollution-free: The workpiece environment is good, environmentally friendly, pollution-free, and has low energy consumption. High degree of automation: Multiple quenching process programs can be developed and stored according to different workpiece requirements, without the need for manual adjustment during the quenching process. The equipment automatically completes quenching, reducing labor intensity. For example, steel bar quenching equipment only requires two people to operate the complete set of equipment.

Good product quality: After quenching, the metallographic structure is finer, the mechanical strength is 10-15% higher than that of resistance furnace treatment, and the product consistency is good. By precisely controlling the heating and cooling processes, the performance of metal workpieces has been effectively improved, resulting in higher strength, toughness, plasticity, and machinability of steel plates.

Wide applicability: Suitable for heat treatment of various metal materials, including quenching, tempering, annealing, normalizing and other processes, and can also be used for welding and melting of metal materials. For example, it is suitable for metal workpieces such as steel bars, steel pipes, and steel plates, especially for workpieces that require enhanced surface hardness and wear resistance. It is widely used in industries such as automobiles and machinery manufacturing.

High equipment reliability: With a unique circuit design, the system is composed of power module units, and the damage of individual power modules cannot affect the operation of the equipment, which significantly improves the reliable operation of the equipment. At the same time, the steel plate heat treatment machine has a simple structure, simple spare parts, small footprint, light weight, and is easy to use, inspect, and maintain.

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Post time: 05-09-2025