+86 133 0307 8975

+86 133 0307 8975

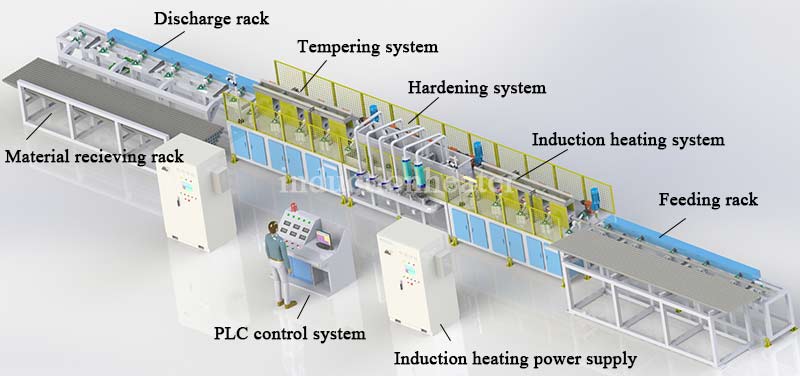

Composition of Long Bar Induction Hardening And Tempering Furnace

【 Quenching power/frequency 】160-1000KW/0.5-4KHz

【 Tempering power/frequency】100-600KW/0.5-2.5KHz

【 Production capacity】0.5-3.5t/h

【 Scope of application】8mm to 120mm

【 Main Application 】Suitable for hardening and tempering heat treatment of steel bars, low-carbon alloy steel, wind turbine bolts, lead screws, and hydraulic cylinder rods.

【 Energy Conversion 】Adopting the method of hot hardening followed by high-temperature tempering, with a power consumption of 420-480 kWh per ton

long bar induction hardening and tempering furnace

1. Loading mechanism, discharging mechanism

2. Input/output roller conveyor (the workpiece rotates while feeding at a uniform speed, and runs smoothly, with adjustable speed and more uniform heating)

3. Hardening Induction Heating System

4. Hardening spray system

5. Tempering induction heating system

6. PLC control panel (including variable frequency speed regulation and temperature control, Huayan industrial computer, remote start, etc.)

7. Hardening air-cooled induction heating power supply range: KGPS/IGBT 250KW-1500KW

8. Tempering air-cooled induction heating power supply range: KGPS/IGBT 250KW0-850KW.

Process Principle Description

The long bar induction heat treatment machine is composed of Forever Electromechanical's unique intelligent intermediate frequency hardening system, intermediate frequency tempering system, closed water cooling system, storage rack, infrared temperature measurement of hardening mechanical feeding device, spray cooling system, tempering mechanical feeding device, feeding rack and central control system. The metal hardening and tempering furnace can harden and high-temperature temper metal workpieces ranging from 20mm to 185mm. The heating method is online continuous heating. The complete production line only requires a crane to lift the workpiece onto the storage rack, and the rest of the actions are automatically completed by the system controlled by PLC. The complete equipment adopts computer automatic control to store, display, automatically record and print the mechanical operating parameters, hardening and tempering parameters, temperature and other parameters of the entire system. The system runs automatically according to the set process parameters, with high production efficiency and strong automatic matching ability.

IGBT Induction Power Supply

Forever Induction Heat Treatment Machine Case

Customer Visit

Workshop

Transportation

Contact Us

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone/Wechat/Whatsapp:+86 13303078975

Navigation

Tel.:+86 133 0307 8975

E-mail: tom@foreverfurnace.com

WhatsApp: +86 133 0307 8975

Add.: Wuqiao Economic Development Zone, Hebei Province, China, Cangzhou, Hebei, China

FOLLOW US