+86 133 0307 8975

+86 133 0307 8975

Jan. 12, 2026

The development advantages of Forever long bar induction hardening and tempering machine are mainly reflected in the following aspects, which make it significantly competitive in the metal heat treatment industry:

1. Efficient and energy-saving, reducing production costs

Rapid heating: Induction heating directly heats the interior of the workpiece through electromagnetic induction, with a very fast heating speed (up to hundreds of degrees Celsius per second), greatly shortening the production cycle and improving efficiency.

Precise temperature control: adopting an automated temperature control system to reduce energy waste, saving about 30% -50% energy compared to traditional resistance furnaces or gas furnaces.

Low oxidation loss: Short heating time, less oxidation and decarburization on the surface of the workpiece, reducing material loss and post-treatment costs.

2. Flexible process and strong adaptability

Multi specification compatibility: long bar induction hardening and tempering furnace can handle long bars with different diameters (such as Φ 20mm - Φ 200mm) and materials (alloy steel, stainless steel, etc.), and adapt to diverse needs by adjusting parameters.

Segmented temperature control: For different temperature requirements of hardening and tempering, segmented precise heating can be achieved to meet complex process requirements.

Automation integration: It is easy to form a fully automatic production line with loading and unloading robotic arms, conveyor lines, etc., suitable for large-scale continuous production.

3. Stable quality and excellent performance

High uniformity: Through multi turn coil design and power adjustment, uniform heating of the rod in both radial and axial directions is achieved, avoiding soft spots or deformation.

Organizational performance optimization: Rapid hardening and tempering can refine grain size, improve material strength, hardness, and fatigue life, especially suitable for key components such as high-strength fasteners and shafts.

Good repeatability: fully digital control, process parameters can be stored and called, reducing human error and ensuring batch consistency.

4. Environmental protection and safety improvement

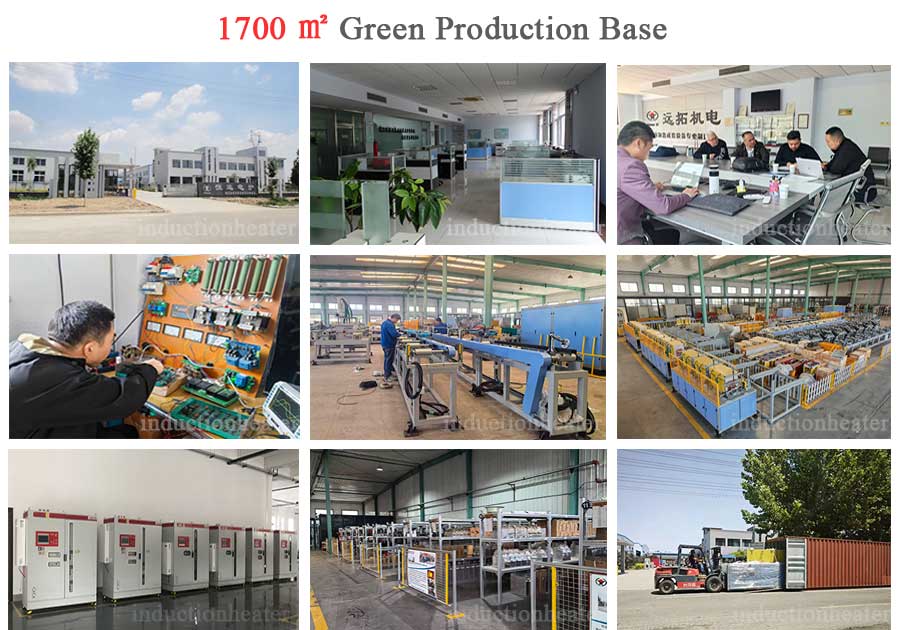

Clean production: no combustion exhaust emissions, low noise, friendly working environment, in line with the trend of green manufacturing.

High equipment safety: adopting isolation and protection design to avoid high temperature radiation and electric shock risks, equipped with emergency stop and fault diagnosis system.

5. Intelligent and digital upgrading

Intelligent monitoring system: real-time monitoring of power, temperature, speed and other parameters, remote monitoring and data analysis through PLC or industrial Internet.

Predictive maintenance: Sensors can provide early warning of equipment abnormalities, reduce downtime, and improve equipment utilization.

Process database: Accumulate and optimize process parameters to provide quick solutions for new materials or new specification products.

6. Industry application expansion

High end manufacturing field: widely used in high-end components such as automotive connecting rods, wind power bolts, and oil drill rods to meet their stringent performance requirements.

Technological iteration promotion: With the advancement of technologies such as ultra-high frequency power supply and dual frequency quenching, equipment capabilities continue to improve and can handle more complex materials and structures.

The development advantages of Forever's long bar induction heat treatment machine lie in high efficiency, energy saving, controllable quality, flexibility and intelligence, which meets the needs of modern manufacturing industry for cost reduction and efficiency improvement, green environmental protection, and high-precision heat treatment. In the future, with the deep integration of sensing technology, artificial intelligence, and the Internet of Things, its advantages will be further amplified, promoting the development of the metal heat treatment industry to a higher level.

If you are also interested in this machine,please don't hesitate to contact us:

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone/Wechat/Whatsapp:+86 13303078975

Navigation

Tel.:+86 133 0307 8975

E-mail: tom@foreverfurnace.com

WhatsApp: +86 133 0307 8975

Add.: Wuqiao Economic Development Zone, Hebei Province, China, Cangzhou, Hebei, China

FOLLOW US