+86 133 0307 8975

+86 133 0307 8975

Jan. 06, 2026

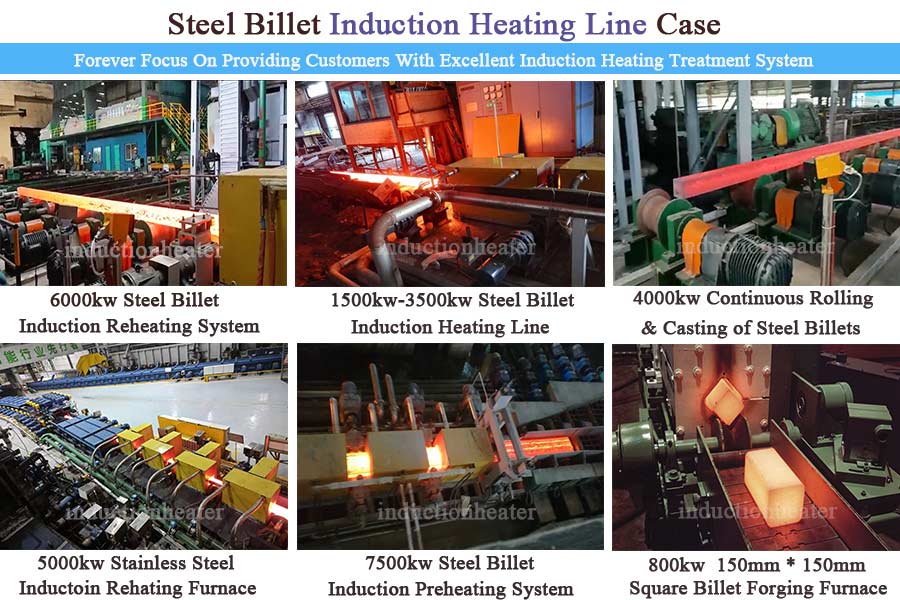

The steel billet induction reheating furnace is a device used in the metallurgical industry to reheat cooled steel billets, in order to increase their temperature and make them suitable for the next process, such as rolling, forging, etc. Here are some basic information about the secondary heating furnace for steel billets:

Classification of steel billet induction reheating furnace:

1. Gas heating furnace: Using gas as fuel, the steel billet is heated by the high-temperature gas generated by combustion.

2. Electric heating furnace: Using electrical energy as the heating source, the steel billet is heated by passing current through conductive materials.

3. Induction heating furnace: Using the principle of induction heating, steel billets are heated through electromagnetic induction.

Working principle of steel billet induction reheating furnace:

1. Gas heating furnace: Gas is burned in the combustion chamber to produce high-temperature gas, and then the steel billet is directly heated by the gas heater or combustion chamber.

2. Electric heating furnace: Heat is generated in an electric furnace through conductive materials (usually resistance heating wires) using current to heat steel billets.

3. Induction heating furnace: Using the changing magnetic field generated by the induction coil, eddy currents are induced in the conductive material (steel billet) inside, causing it to generate heat.

Application of steel billet induction reheating furnace:

The steel billet induction heating machine is mainly used in the following fields:

1. Rolling: The steel billet needs to reach a certain temperature before the rolling mill to ensure its plastic deformation performance during the rolling process.

2. Forging: In the forging process, reheating can make the steel billet more prone to plastic deformation, improving forging efficiency and quality.

3. Heat treatment: In some heat treatment processes, it is necessary to reheat the steel billet to achieve corresponding adjustments in structure and properties.

If you are also interested in this machine,please don't hesitate to contact us:

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone/Wechat/Whatsapp:+86 13303078975

Navigation

Tel.:+86 133 0307 8975

E-mail: tom@foreverfurnace.com

WhatsApp: +86 133 0307 8975

Add.: Wuqiao Economic Development Zone, Hebei Province, China, Cangzhou, Hebei, China

FOLLOW US