+86 133 0307 8975

+86 133 0307 8975

Jan. 15, 2026

Forever steel plate induction hardening mahcine is a professional industrial furnace used for quenching steel plates, especially medium thick plates, high-strength steel plates, wear-resistant steel plates, etc. Its core task is to rapidly, uniformly, and controllably cool steel plates heated to austenitization temperature to obtain the desired martensitic or bainitic structure, thereby significantly improving the hardness, strength, and wear resistance of the steel plates.

The steel plate induction hardening furnace is not a single furnace body, but a complete heat treatment production line that integrates heating, insulation, rapid cooling, and control systems. Its process objectives are clear:

Realize uniform and rapid cooling of the steel plate core surface, reach the critical cooling rate, and avoid pearlite transformation.

Minimize the deformation and residual stress of steel plates during quenching process.

Ensure the uniformity and stability of steel plate performance (hardness, strength).

Core job characteristics and advantages

High and controllable cooling intensity: High pressure and high flow injection can achieve extremely high cooling rates, meeting the quenching requirements of the most demanding materials. Partition control achieves two-dimensional cooling uniformity.

Excellent deformation control capability: The quenching roller/restraint technology is its core advantage that distinguishes it from ordinary cooling systems. It can produce quenched steel plates with extremely high flatness, reducing the difficulty and scrap rate of subsequent straightening.

Performance uniformity and stability: Model based automatic control and real-time feedback ensure high consistency in steel plate performance between batches and between different batches.

High automation and intelligence:

One click production: After the operator inputs information such as steel grade and specifications, the system automatically calls the process curve and executes it.

Data traceability: Record the heating and cooling process parameters and temperature curves of each steel plate throughout the entire steel plate hardening machine, bind them with performance data, and achieve full lifecycle quality traceability.

Predictive maintenance: Monitor the status of critical equipment (such as water pumps and valves) and alert for faults.

High reliability and durability: The equipment design fully considers harsh working conditions such as high heat shock, high humidity, and high load, using corrosion-resistant materials and special seals, with a long maintenance cycle.

If you are also interested in this machine,please don't hesitate to contact us:

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone/Wechat/Whatsapp:+86 13303078975

Navigation

Tel.:+86 133 0307 8975

E-mail: tom@foreverfurnace.com

WhatsApp: +86 133 0307 8975

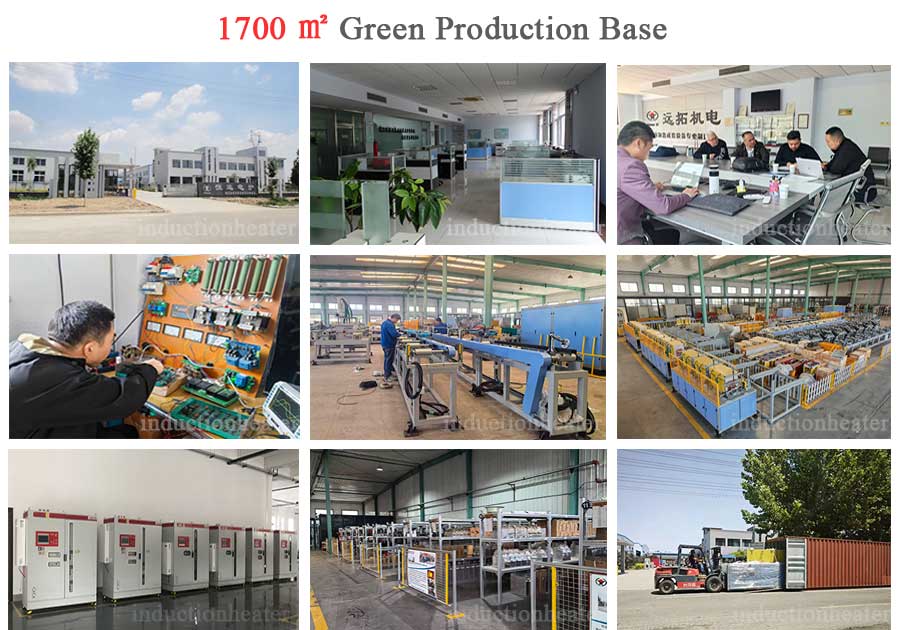

Add.: Wuqiao Economic Development Zone, Hebei Province, China, Cangzhou, Hebei, China

FOLLOW US